1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

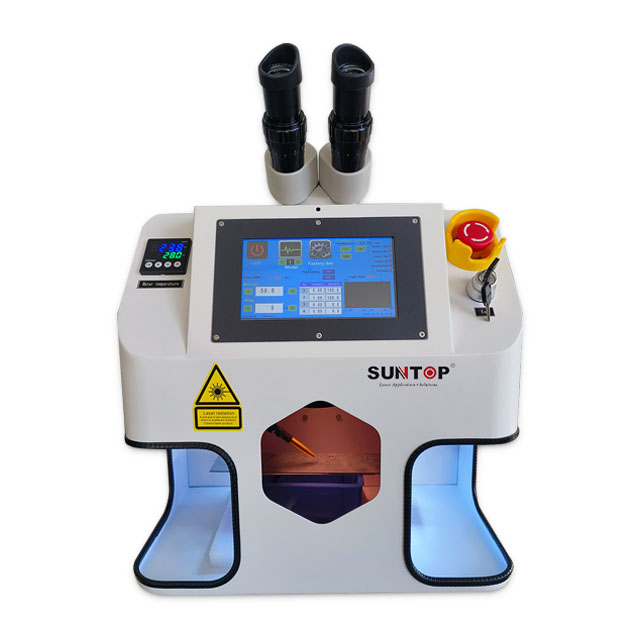

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

5. Can I perform welding on-site?

Yes, the portable air-cooled laser spot welder's lightweight design makes it ideal for field welding operations. Without the need for complex water-cooling systems, you can conveniently use it across various working environments.

6. Does operating this welder require professional training?

While some basic welding knowledge is helpful, the welder features a user-friendly interface that typically allows users to get started quickly. We also provide detailed operating manuals and training materials to ensure safe and effective equipment use.

7. What safety precautions should be observed during welding?

When using welding equipment, always wear appropriate personal protective gear (such as laser goggles and gloves), avoid direct contact with the laser beam, and ensure the work area is well-ventilated to minimize smoke and gas buildup.

8. What maintenance is required for this welder?

Thanks to its air-cooled technology, maintenance is relatively straightforward. Regularly inspect and clean the optical path and welding components to ensure proper operation. Additionally, periodically clean the fans to prevent dust buildup that could impair heat dissipation.

9. How effective is the welding, and can it guarantee an aesthetically pleasing result?

The portable air-cooled laser spot welder achieves high-precision welding, producing joints that are both visually appealing and robust. It is suitable for applications demanding high-quality weld appearance. Post-weld processing is typically unnecessary, allowing immediate use of the welded components.