1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

5. How does a laser welding machine for gold jewelry work?

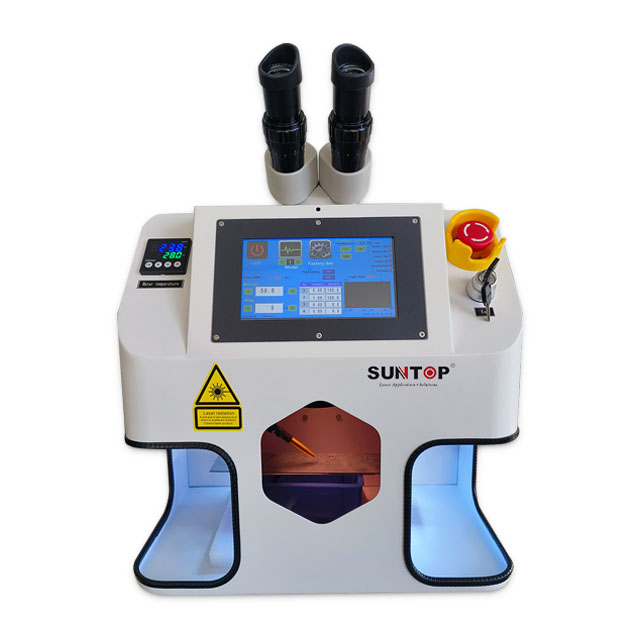

A laser welding machine for gold jewelry uses a highly concentrated laser beam to instantly heat the metal, melting the weld point and forming a strong bond as it cools. This technology is precise and highly effective, suitable for various intricate designs.

6. What are the advantages of laser welding?

Compared to traditional welding methods, laser welding offers higher precision, a smaller heat-affected zone, and minimal material loss. Additionally, it can handle intricate craftsmanship and complex shapes, ensuring the jewelry's aesthetic appeal and structural integrity.

7. Does laser welding damage gold jewelry?

Proper use of a laser welding machine does not damage gold jewelry. The minimal heat generated effectively avoids thermal impact on surrounding areas, ensuring both strength and appearance at the weld point.

8. Can I use this machine to weld other metals?

Yes, laser welding machines for gold jewelry typically weld multiple metals, including silver, aluminum, copper, and more. Please confirm compatible metal types according to the equipment specifications.

9. What skills are required to operate a laser welding machine?

While some training is necessary, these machines are generally designed to be user-friendly with intuitive interfaces, suitable for both beginners and experienced professionals.

10. What should be noted for laser welding machine maintenance?

Regularly inspect and clean the machine's lenses and optical paths to ensure they remain free of dust and contaminants. Follow the manufacturer's maintenance guidelines and schedule professional servicing to extend the equipment's lifespan.

11. How fast and efficient is laser welding?

Laser welding operates at high speeds, making it suitable for efficient production and repair tasks. It can complete complex welding jobs in minimal time, significantly boosting productivity.