1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

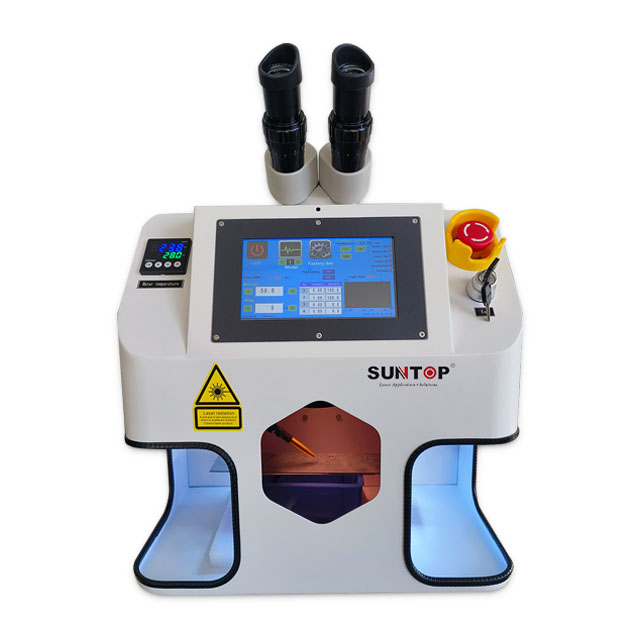

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

5. What kind of training is required to operate a laser spot welder?

Although laser spot welders are generally designed to be intuitive, professional training is recommended to fully utilize the equipment's capabilities. During training, operators will learn safe operating procedures, as well as how to set welding parameters and perform routine maintenance.

6. Does the laser spot welder require special maintenance?

Laser spot welders are generally simple to maintain, but regular inspections of the laser source, cooling system, and optical path to ensure they are in good working condition are necessary.

7. What is the basis for selecting the power of a laser spot welder?

The power selection depends on the thickness and type of the welded material. Generally, thicker materials require higher welding power to ensure the strength and quality of the welded joint.

8. Can laser spot welders be used for jewelry repair?

Yes. Laser spot welders are well suited for jewelry repair, as they can precisely weld small parts to restore the beauty and integrity of jewelry without damaging other parts.

9. How does the cost of laser spot welding compare to traditional welding?

Although the initial investment of the laser spot welding machine may be high, due to its high efficiency, precision and reduced material waste, it can significantly reduce production costs and improve economic benefits in the long term.