1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

5. What is a 6000W fiber laser welding machine?

6000W fiber laser welding machine is a device that uses fiber laser technology for metal welding. It has a high power output (6000 watts) and can achieve fast and high-quality welding.

6. What are the advantages of this welding machine?

High welding speed: greatly improves production efficiency.

High-quality welding effect: ensures that the weld is flat and dense, and reduces post-processing.

Small heat-affected zone: reduces the risk of deformation of surrounding materials.

Low energy consumption: high energy utilization rate, saving electricity.

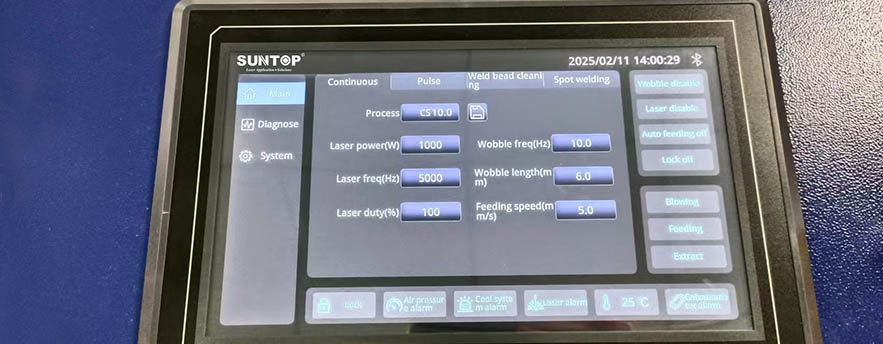

Easy operation: the automated control system reduces labor intensity.

7. How difficult is the maintenance of this equipment?

The maintenance of the fiber laser welding machine is relatively simple. Due to its compact structure and reduced wear, daily maintenance mainly focuses on cleaning and regular inspections.

8. What kind of training is required to operate a 6000W fiber laser welding machine?

Operators usually need to receive basic laser safety training, as well as professional training in equipment operation and program settings to ensure safety and welding quality.

9. What are the safety precautions for using a 6000W fiber laser welding machine?

Wear appropriate personal protective equipment (such as laser protective glasses).

Ensure that the working environment is well ventilated to avoid the accumulation of harmful gases.

Follow the safety instructions and operating procedures in the equipment operating manual.

10. Can the functions and configurations of this equipment be customized?

Many manufacturers offer customization options to adjust the functions and configurations of laser welding machines according to the specific needs of customers.