1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

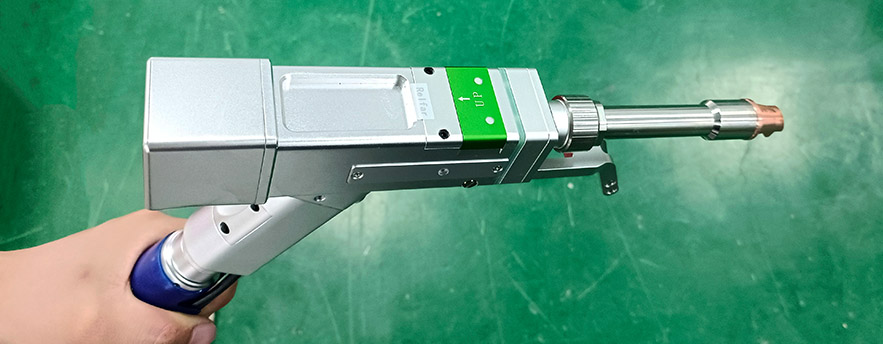

5. What is a 4-in-1 handheld laser welding machine?

The 4-in-1 handheld laser welding machine is a laser device that integrates welding, cutting, marking and cleaning functions, providing flexible and efficient solutions for a variety of industrial applications.

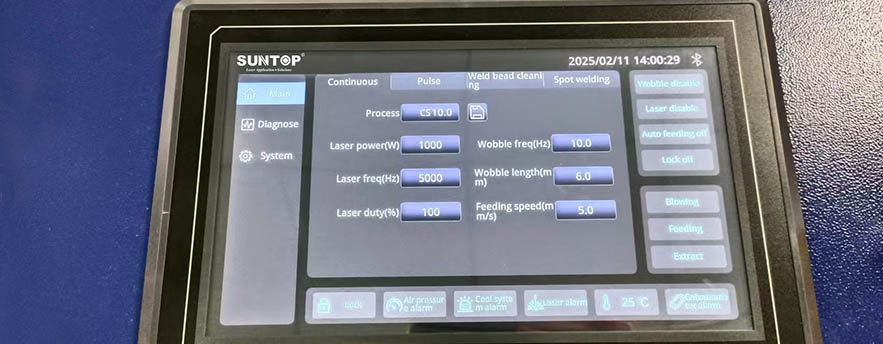

6. How difficult is the operation?

The 4-in-1 handheld laser welding machine is designed to be user-friendly, equipped with a simple operating interface, and the operation process is relatively simple. Generally speaking, after simple training, users can quickly master the operating skills.

7. What should be paid attention to during maintenance?

The equipment usually needs to clean the laser head and optical lens regularly to ensure the smoothness of laser transmission. At the same time, the power supply and cooling system of the equipment are regularly checked to ensure the stable operation of the equipment.

8. How safe is laser welding?

The equipment is usually equipped with safety protection measures such as laser protection cover and emergency stop button. Operators should wear appropriate protective equipment and follow safe operating specifications.

9. How efficient is the work?

The 4-in-1 handheld laser welding machine can achieve fast welding, cutting, cleaning and weld cleaning, and its efficiency is much higher than that of traditional welding methods. It is particularly suitable for mass production and welding of complex workpieces.

10. What is the power consumption of the equipment?

The power consumption of the 4-in-1 handheld laser welding machine varies slightly depending on the model and function. Generally speaking, laser welding is more energy-efficient than traditional welding methods. You can ask the supplier for specific power consumption data.