Suzhou Suntop Laser Technology Co., Ltd. Start working and developing in the laser technology from the year 2006. We are a high-tech modern enterprise specializing in R & D and production of laser equipment. Our company has a standard workshop for laser cutting machine, laser welding machine and laser marking machine totally about 15,000 square meters and 80 employees, including 8 laser engineers and mechanical engineers who more than 10 years’ experience in laser industry.

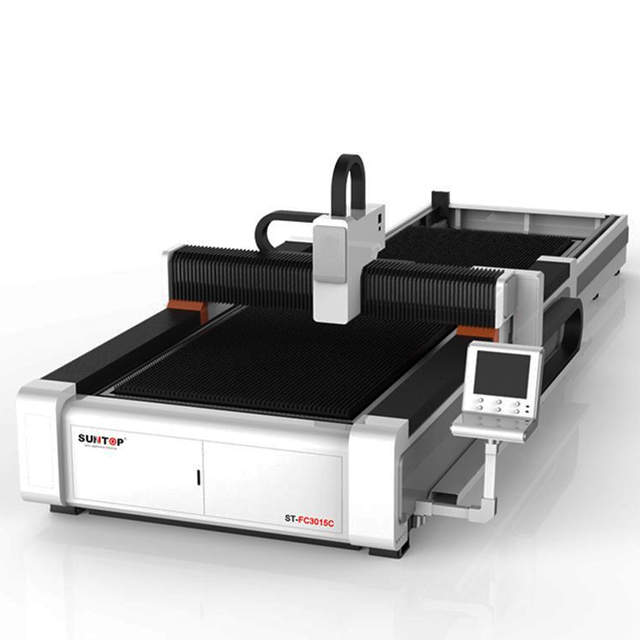

SUNTOP Laser manufactures a comprehensive range of CNC laser cutting machine, fiber laser marking machine, laser welding machine and different kinds of automatic laser systems powered by world-leading laser brands, all our laser machines has gaind the Europe CE standard and USA FDA certificate.- Products

- Fiber laser cutting machines

- Single table series

- Full enclosed with dual exchanged table

- Small cutting size series

- Sheet metal and tubes laser cutting machine

- Laser tubes cutting machine

- Automatic laser cutting machine

- Automatic laser tube cutting machine

- Dual exchange platform without enclosed

- Dual exchange platform with tube cutting

- Laser marking machines

- Laser welding machines

- 3D crystal laser inner engraving machine

- CO2 laser cutting and engraving machine

- Laser cleaner machine

- Laser consumables and accessories

- Fiber laser cutting machines

- Case & Applications

- Download

- About Us

- Contact Us