1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

5. What are the advantages of laser welding?

Laser welding has the advantages of high precision, high strength, small heat-affected zone, and fast welding speed, which can ensure good weld appearance and high quality.

6. What are the benefits of using this equipment for cleaning?

Laser cleaning can effectively remove oil, oxide layer and other dirt, and the process does not require chemical reagents, which is more environmentally friendly and can improve the quality of subsequent processing.

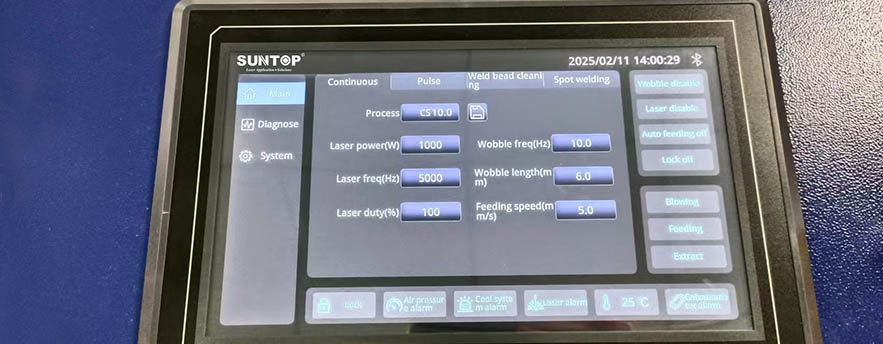

7. How difficult is the operation of this equipment?

The equipment is equipped with a modern user interface and intelligent control system, which is relatively simple to operate and usually requires less training time to get started.

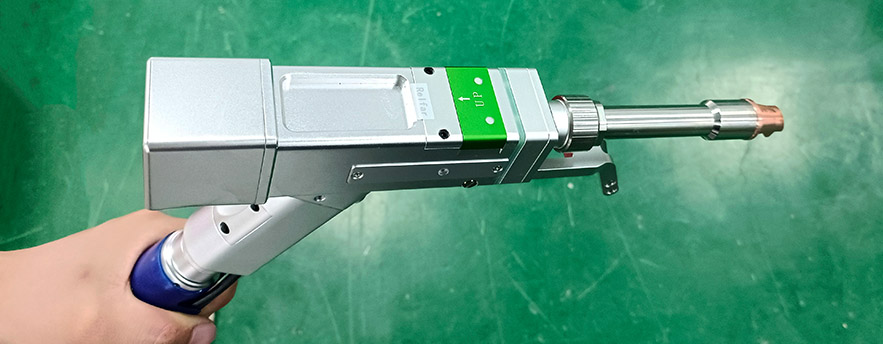

8. How portable is the equipment?

The handheld design makes the equipment easy to carry and operate, suitable for on-site operations in different occasions, and improves operational flexibility.

9. What should be paid attention to in terms of maintenance?

Regularly check the cleanliness of the laser transmitter and optical path system to ensure that the equipment is in good working condition, and perform regular maintenance according to the maintenance manual provided by the manufacturer.

10. What industries are applicable to this equipment?

The 4-in-1 handheld laser welding machine is suitable for many industries such as automobile manufacturing, electronics industry, mechanical processing, construction, aerospace, etc.