1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

5. How fast is the welding speed of the equipment?

The welding speed depends on the type of material, thickness and welding requirements. Generally speaking, the speed of the 6000W laser welding machine is significantly higher than that of traditional welding equipment, which can improve production efficiency.

6. Is the maintenance cost of the equipment high?

The structure of the 6000W laser welding machine is relatively simple and maintenance is relatively convenient. Due to the long life of the components and low failure rate, the maintenance cost of long-term use is generally low.

7. What are the advantages of laser welding compared with traditional welding?

Laser welding has the advantages of high speed, high precision, small heat-affected zone, and environmental protection. Compared with traditional welding (such as arc welding), it can significantly improve welding quality and efficiency.

8. Can automated welding be achieved?

Yes, the 6000W laser welding machine can be integrated with the automated production line to achieve automatic welding, improve production efficiency, and reduce labor costs.

9. What should be paid attention to when using the laser welding machine?

When using the laser welding machine, you should pay attention to laser safety, wear appropriate protective equipment (such as laser protective glasses), ensure good ventilation in the work area, and comply with the equipment operating procedures.

10. Does the equipment consume a lot of energy?

Compared with traditional welding processes, laser welding usually consumes less energy because its high efficiency can complete the welding task in a shorter time, reducing energy waste.

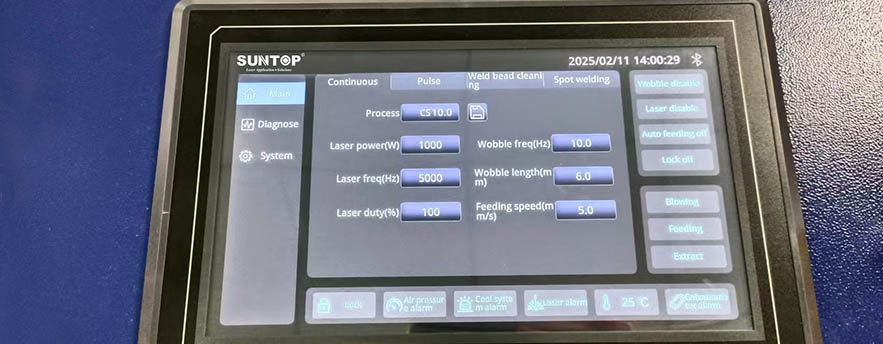

11. Does the equipment support multiple welding processes?

The 6000W laser welding machine not only supports traditional welding processes, but also can perform multiple functions such as cutting, cleaning and weld cleaning, making it more flexible and practical.