1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

5. What is the precision and quality of the welds?

This equipment utilizes advanced laser technology to achieve high-precision welding, ensuring smooth, seamless joints that significantly preserve the jewelry's aesthetic appeal and intricate craftsmanship.

6. Is operation complicated?

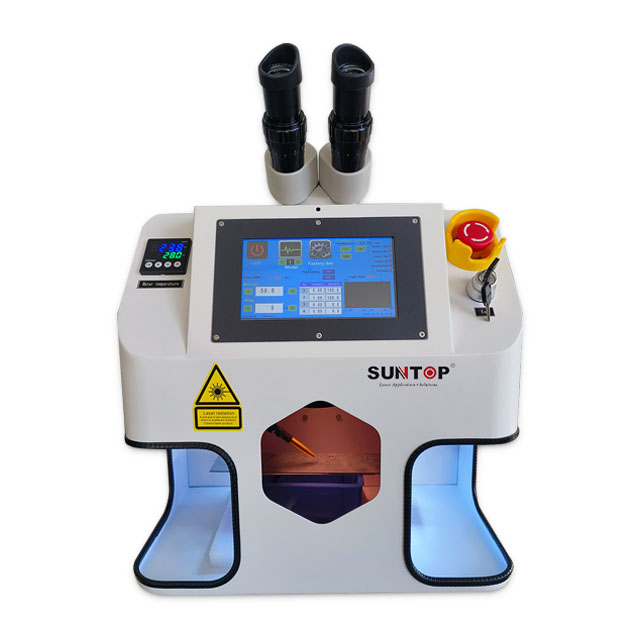

The equipment features a user-friendly design with an intuitive touchscreen interface. Users typically require only brief training to master operation and quickly adapt to welding tasks.

7. What are the maintenance requirements?

The laser jewelry welder requires minimal upkeep, primarily involving periodic cleaning of the laser head and inspection of the optical path system to ensure consistent performance.

8. Does laser welding affect the jewelry's color or luster?

When using proper settings and welding techniques, laser welding does not alter the jewelry's color or luster, producing natural and aesthetically pleasing results.

9. Are customized welding solutions available?

Yes, the equipment supports adjustment of multiple welding parameters to provide personalized welding according to customer requirements.