1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

5. Is the equipment complicated to operate?

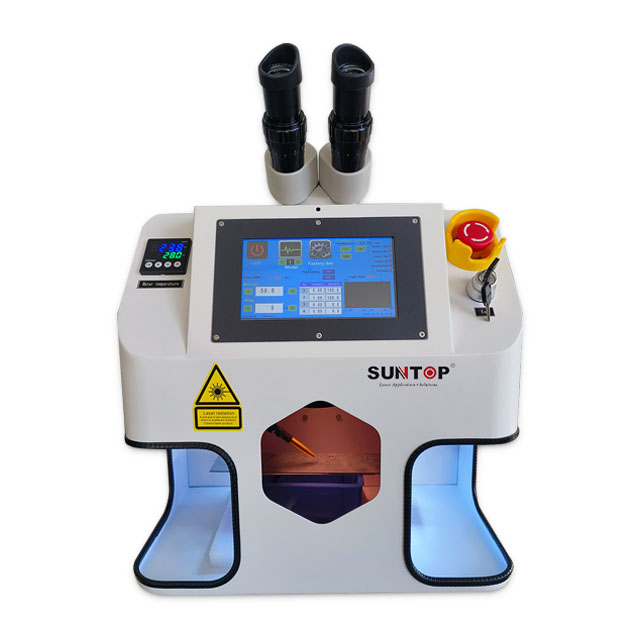

Jewelry laser spot welders are typically designed with user-friendly interfaces that are easy to learn and use. After basic training, operators can quickly master the equipment's operation, thereby improving production efficiency.

6. What are the welding results like with laser spot welding?

Laser spot welding delivers high-quality welds with smooth, seamless joints that offer exceptional strength and durability. The minimal heat-affected zone design effectively prevents material deformation and damage, preserving the jewelry's aesthetic appeal and structural integrity.

7. What are the maintenance costs for jewelry laser spot welders?

Maintenance costs for jewelry laser spot welders are relatively low, as the equipment design typically prioritizes simplified maintenance requirements. Regular cleaning of the laser head and periodic checks of operational status suffice. The equipment boasts a long service life with low maintenance frequency.

8. How significant is the thermal impact on jewelry during this process?

Due to the extremely small heat-affected zone during laser spot welding, the thermal influence on jewelry materials is minimal. This effectively reduces risks of deformation and color changes caused by high temperatures.

9. Does this equipment support custom welding parameters?

Yes, jewelry laser spot welders typically support custom settings for multiple welding parameters. Users can adjust parameters such as power, welding speed, and pulse width according to different application requirements.