1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

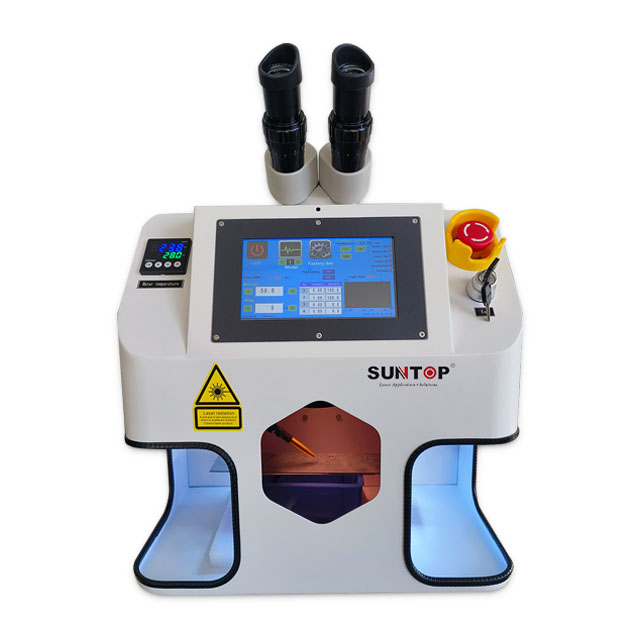

5. How to use the mini jewelry laser spot welding machine?

Please read the operation manual carefully before use. The general steps include setting the laser power, selecting the appropriate welding mode, placing the jewelry to be welded in the designated position, and then starting the welding process.

6. What are the results of laser spot welding?

Laser spot welding achieves high-precision welding, producing strong and aesthetically pleasing welds, suitable for the creation and repair of delicate jewelry.

7. Will the welding process cause heat damage to surrounding materials?

The mini jewelry laser spot welding machine uses low heat-affected zone (HAD) technology, effectively reducing the heat generated during welding and protecting the delicate craftsmanship of the jewelry.

8. Is the maintenance of this welding machine complicated?

Maintenance of the welding machine is relatively simple. Regularly clean the laser path and connectors to ensure the equipment is working properly. Detailed maintenance instructions can be found in the user manual.

9. Can I use the mini jewelry laser spot welding machine at home?

Yes, the mini jewelry laser spot welding machine has a compact design suitable for home use. Please ensure it is used and operated in a well-ventilated environment.