In addition to being closely related to power, the speed and effect of laser cleaning are also affected by many other factors. The following is a detailed analysis of some important factors:

1. Laser wavelength

The laser wavelength has a significant impact on the cleaning effect. Lasers of different wavelengths have different absorption capabilities for various materials and pollutants. Generally:

Short-wavelength lasers: such as ultraviolet lasers (such as 355nm), have more concentrated energy, which is convenient for combining with short-wavelength materials (such as plastics or certain coatings), and are suitable for processing surface coatings and fine pollutants.

Long-wavelength lasers: such as infrared lasers (such as 1064nm), are more suitable for metal surfaces, can penetrate deeply and heat materials, and are suitable for removing oxides and rust on metal surfaces.

Choosing the right wavelength can effectively improve the cleaning speed and removal rate.

2. Beam quality

The beam quality is mainly determined by the divergence and focusing degree of the laser beam. Good beam quality can improve energy concentration, thereby improving cleaning efficiency:

High beam quality: It can achieve a smaller spot area, which helps to improve the local thermal effect and thus speed up the cleaning speed.

Focusing accuracy: Correct focusing can ensure that the laser energy is effectively concentrated on the surface of the dirt and reduce energy waste.

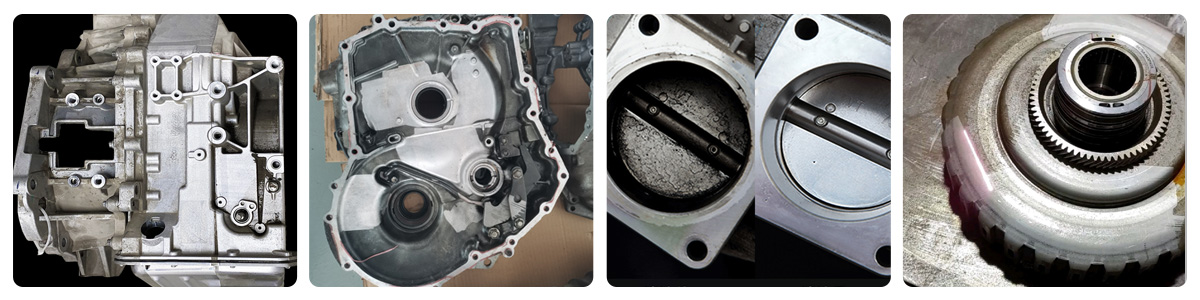

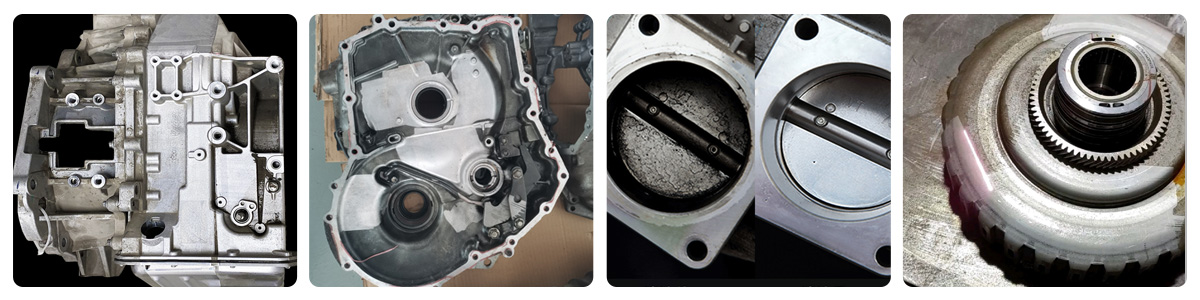

3. Material properties

Thermophysical properties of different materials (such as thermal conductivity, melting point, specific heat capacity, etc.) affect the cleaning speed and effect:

Thermal conductivity: Materials with high thermal conductivity (such as aluminum and copper) can conduct heat quickly, which may reduce the cooling effect and thus affect the cleaning effect; while materials with low thermal conductivity may heat faster and improve the cleaning efficiency.

Melting point and decomposition temperature: For polymers and coatings, their melting point and decomposition temperature must be fully understood to ensure that the substrate is not damaged during the cleaning process.

It is crucial to select laser parameters that match the material to be cleaned.

4. Cleaning environment

The conditions of the cleaning environment (such as humidity, airflow, temperature, etc.) will also affect the cleaning effect:

Humidity: Appropriate humidity can increase the absorption rate of lasers by certain materials, thereby improving the cleaning effect. However, excessive humidity may cause laser scattering, which in turn reduces the cleaning efficiency.

Airflow: The airflow conditions in the cleaning area can affect the evaporated pollutants. If the airflow is too strong, it may carry away the gases and particles generated during the cleaning process, thereby affecting the thoroughness of the cleaning.

Temperature: The temperature of the surrounding environment may also affect the thermal properties of the material, so the material may be more susceptible to damage when cleaning in a high temperature environment.

5. Laser scanning speed and mode

The moving speed and working mode of the laser during cleaning (such as single scan, overlapping scan) are also important factors that determine the cleaning speed and effect:

Scanning speed: Too fast may result in failure to fully act on the dirt, while too slow may result in unnecessary heat-affected areas. Therefore, it is necessary to determine the optimal scanning speed through experiments.

Effort-saving mode: Using a certain overlap rate can improve the uniformity of cleaning, but its range needs to be controlled to avoid material damage caused by excessive power.

The efficiency of laser cleaning technology is not only directly related to the laser power, but also affected by multiple factors such as laser wavelength, beam quality, material properties and cleaning environment. Paying attention to the combined effect of these factors can more effectively optimize the laser cleaning process and achieve higher cleaning efficiency and effect. In application, it is necessary to reasonably select and adjust the laser parameters according to specific cleaning needs and environmental conditions. Click here for more information now