Laser welding of stainless steel has several advantages that make it increasingly popular in industrial applications. Here are some of the main advantages of laser welding of stainless steel:

1. High-precision welding

Laser welding can precisely control the energy input during the welding process to form a very fine weld pool. This makes the size of the weld joint controllable, enabling the welding of tiny components and meeting high-precision requirements.

2. Low heat-affected zone

The heat input during laser welding is relatively low, resulting in a small heat-affected zone (HAZ) in the welding area. This helps to reduce the deformation and grain coarsening of stainless steel during welding, thereby maintaining the mechanical properties and corrosion resistance of the material.

3. Fast welding speed

The welding speed of laser welding is generally higher than that of traditional welding methods, which significantly improves production efficiency and is suitable for large-scale production and rapid manufacturing requirements.

4. Good welding quality

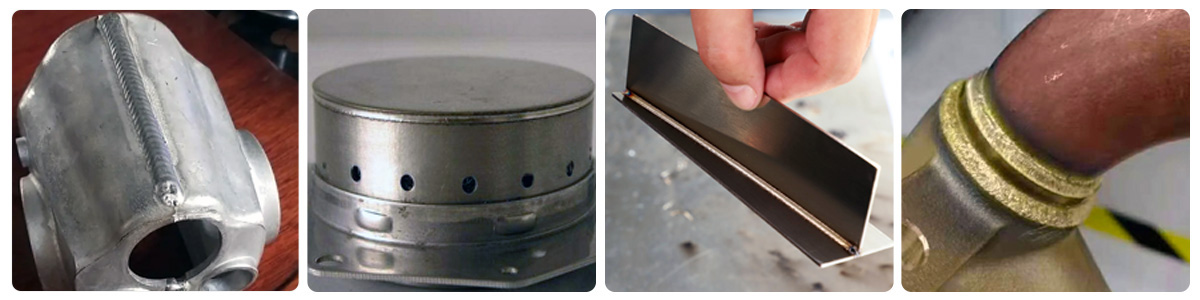

Due to the fine control of the laser welding process, the weld joint can obtain uniform fusion depth and good bonding strength, thereby ensuring welding quality. At the same time, due to the less generation of oxides during welding, the appearance of the weld is also more beautiful.

5. Wide range of applications

Laser welding is capable of welding a variety of thicknesses and types of stainless steel materials, including thin and thick plates. It is also capable of welding different types of stainless steel, which increases its flexibility in application.

6. Non-contact operation

Laser welding is a non-contact welding method that does not require physical contact, which can reduce mechanical damage to the workpiece during welding and is suitable for welding precision parts.

7. Automation is possible

Laser welding systems can be combined with robots and automated production lines to achieve fully automatic welding. This not only improves production efficiency, but also reduces labor costs and improves production consistency.

8. Environmentally friendly

Laser welding produces less smoke and relatively low pollutant emissions, which meets modern environmental protection requirements. This makes it a more environmentally friendly welding process option.

9. Diversity of welding materials

Laser welding can not only weld stainless steel, but also weld dissimilar materials with other materials (such as aluminum, copper, etc.), expanding its application areas.

Laser welding of stainless steel has become an important welding technology in modern manufacturing with its high efficiency, high precision and excellent welding quality, and is widely used in many industries such as automobiles, aerospace, medical devices, and electronic equipment. Click here for more information