When evaluating the long-term economic benefits of laser rust removal, a comprehensive analysis must be conducted across three primary aspects: efficiency, material protection, and environmental benefits.

1. Efficiency Comparison

● Analysis of Laser Rust Removal Speed and Accuracy

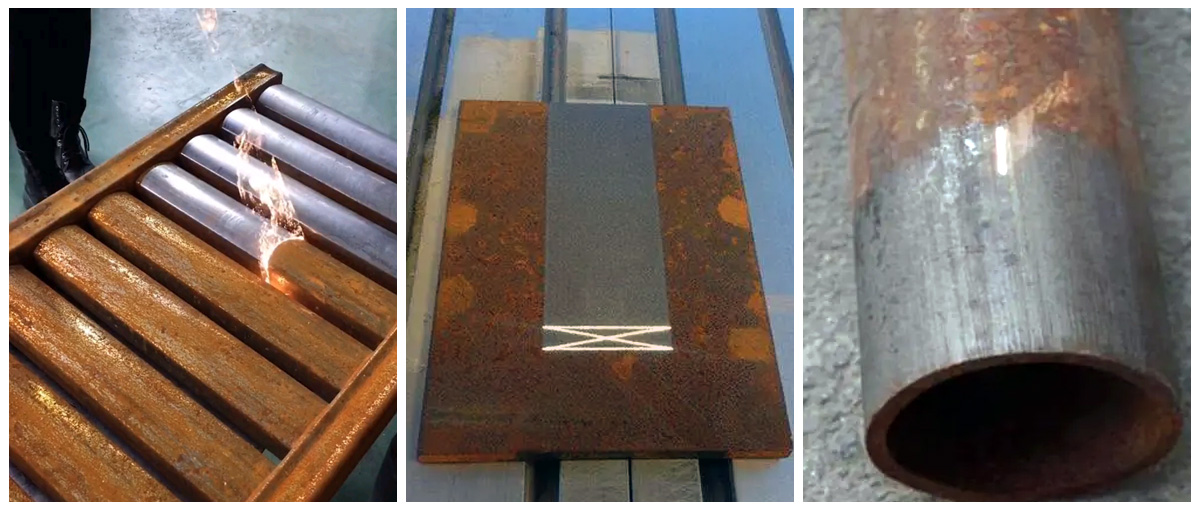

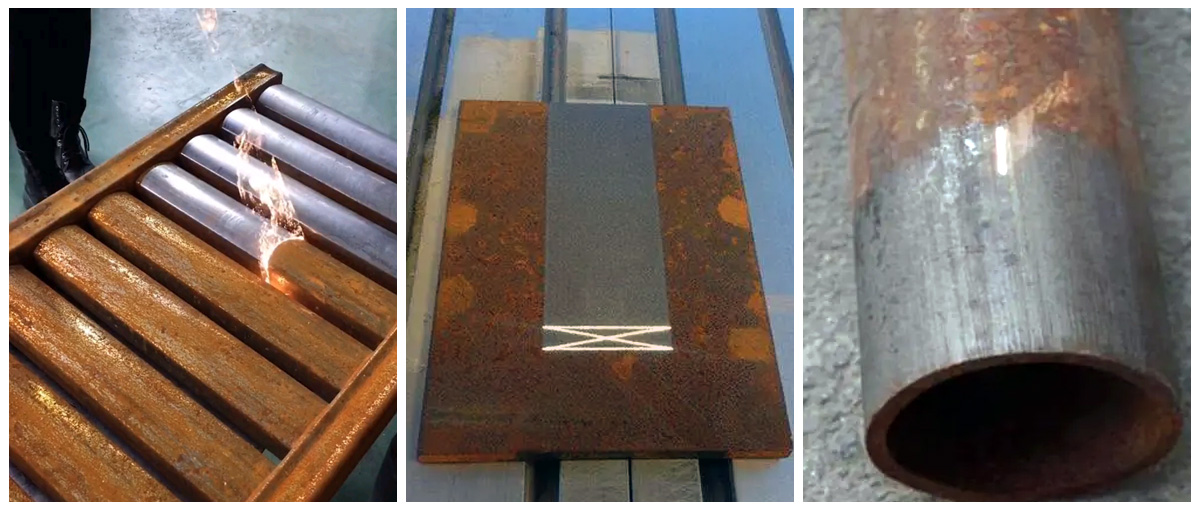

Laser rust removal technology is renowned for its high efficiency. The laser beam can be focused onto the rusted surface in a short time, rapidly removing rust without damaging the substrate. Compared to traditional rust removal methods, laser rust removal significantly accelerates processing speed. It offers higher precision, particularly on complex or delicate surfaces, reducing the need for secondary operations.

● Time Savings in Production Workflows

The rapid nature of laser rust removal enables operators to complete more tasks in less time. This enhances overall productivity in manufacturing environments, shortens project delivery cycles, and saves valuable time and associated costs for businesses. For projects requiring frequent rust removal, the time advantage of laser technology is particularly pronounced.

2. Material Protection

● Impact and Wear of Rust Removal Methods on Substrates

Laser rust removal minimally affects substrates, causing virtually no wear or damage to metal surfaces. This preserves the structural integrity of treated materials, reducing replacement costs due to excessive wear.

In contrast, traditional rust removal methods (such as chemical and mechanical rust removal) may damage the substrate, increasing subsequent maintenance and repair costs.

● Surface Cleanliness After Rust Removal and Subsequent Processing Costs

Laser rust removal provides extremely high surface cleanliness, reducing preparatory work for subsequent processes (such as spraying, plating, etc.). Cleanliness directly impacts coating adhesion and lifespan, further reducing the frequency and cost of subsequent maintenance.

3. Environmental Benefits

● Economic Impact of Reduced Waste and Chemical Usage in Laser Rust Removal

Laser rust removal requires minimal chemical usage, significantly reducing both production waste and associated disposal costs. It also effectively minimizes environmental pollution risks.

By adopting laser technology, businesses can lower capital expenditures on chemical procurement and storage, enhancing overall economic efficiency.

● Compliance Advantages

As environmental regulations tighten, businesses must consider eco-standards when selecting rust removal methods. Laser rust removal, favored for its low-emission characteristics, ensures compliance while minimizing fines and regulatory costs.

Investing in environmentally friendly technologies like laser rust removal may also qualify companies for tax incentives or subsidies, bolstering their market competitiveness.

Laser rust removal technology demonstrates significant economic advantages in efficiency, material preservation, and environmental benefits. Despite higher initial investment, laser rust removal delivers substantial long-term operational cost savings and enhanced productivity, ultimately yielding greater economic returns. Considering the long-term economic benefits of laser rust removal when selecting rust removal technologies will help businesses gain a competitive edge. Click here for more information