Laser tube cutting machines are widely used in multiple industries, especially in the automotive, aerospace and construction fields. Its efficient and precise cutting capabilities enable it to bring significant efficiency improvements and cost reductions to the production processes of various industries. The following is an analysis of applications in different fields:

1. Automotive industry

● Application scenarios

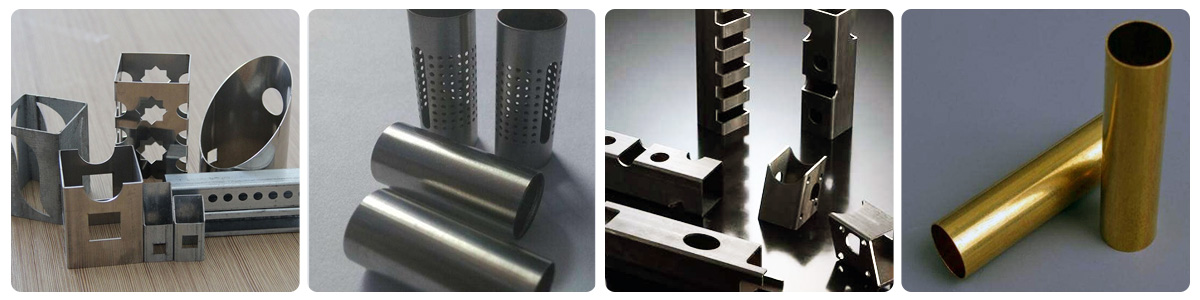

In the automotive manufacturing process, laser tube cutting machines are mainly used to cut body structural parts, exhaust pipes, chassis brackets and other parts.

● Improve production efficiency

High-speed laser cutting can complete the cutting of complex shapes in a short time, allowing manufacturers to respond quickly to market demand and shorten production cycles. At the same time, the high precision of laser cutting makes the splicing connection of parts tighter and reduces the error during assembly.

● Reduce costs

Precise cutting reduces material waste and reduces the cost of raw materials. In addition, laser cutting reduces the need for subsequent processing (such as grinding and welding), further reducing production costs.

2. Aerospace industry

● Application scenarios

In the aerospace field, laser tube cutting machines are widely used to cut high-strength alloys, composite materials and lightweight materials, which are usually used in aircraft fuselages, wing structures and engine components.

● Improve production efficiency

Laser tube cutting machines can achieve fine cutting of complex geometric shapes, meeting the aerospace industry's requirements for high precision and high quality. At the same time, due to the small heat-affected zone during laser cutting, the original strength and properties of the material can be maintained, post-processing procedures can be reduced, and overall work efficiency can be improved.

● Reduce costs

By reducing material waste and speeding up production cycles, companies can achieve good economic benefits. In addition, efficient cutting and precise finished products reduce rework rates and significantly reduce cost expenditures.

3. Construction industry

● Application scenarios

In the construction industry, laser tube cutting machines are used in the production of metal components, such as steel structures, pipes, and decorative metal panels.

● Improve production efficiency

With laser tube cutting machines, diverse and complex design requirements can be completed in a short time, supporting personalized customization. During the construction phase, this high-speed and high-precision production can quickly meet the needs of various types of construction projects.

● Reduce costs

Laser cutting can reduce costs in actual construction by reducing material cutting errors and improving process optimization. It avoids additional costs caused by material waste, while improving assembly accuracy and reducing on-site construction time and labor costs.

Laser tube cutting machines have been widely used in many fields such as automobiles, aerospace, and construction due to their efficient cutting capabilities and high-precision processing advantages. These applications not only improve production efficiency, but also effectively reduce the production costs of enterprises. With the continuous advancement of technology and the increase in market demand, laser tube cutting technology will continue to play a greater role in the future. Click here for more information

Future Development Trends With the advancement of science and technology, new laser technologies are developing rapidly, especially the rise of fiber laser technology. Fiber lasers have attracted widespread attention for their high energy efficiency, excellent processing accuracy, and low maintenance costs. This technology not only improves the efficiency of metal cutting and welding, but also provides opportunities for the use of lasers in more complex materials and applications, such as thin-walled materials and special shapes. In addition, the continuous maturity of new laser sources such as UV lasers and CO2 lasers will further expand the application scope of laser processing.

Industrial intelligence and automation are another important development trend. Laser processing equipment is gradually integrating with the Internet of Things (IoT), artificial intelligence (AI), and big data technologies to optimize production processes through real-time monitoring and intelligent analysis. This change enables companies to enhance production flexibility while improving production efficiency and reducing manual intervention. The integration of robotics technology also plays an important role in laser processing, which not only improves the accuracy of operations, but also can cope with complex manufacturing needs.

In the context of sustainable development and environmental protection technology, laser technology is combined with the concept of green manufacturing to reduce environmental impact. New laser processing methods not only reduce material waste, but also improve energy efficiency. In addition, the non-contact nature of laser processing makes the processing of renewable materials more efficient, helping companies achieve green production goals. These trends indicate that laser technology will not only focus on efficiency and cost in the future, but will also actively pursue environmental protection and sustainable development. Click here for more information

Laser tube cutting machines play an increasingly important role in modern manufacturing. Due to its high precision, high efficiency and flexibility, laser tube cutting technology can meet the industry's demand for high-quality, complex-shaped parts. In the fields of aerospace, automobile manufacturing, construction and mechanical processing, the application of laser tube cutting machines helps to improve production efficiency, reduce waste, and improve the overall quality of products. These advantages make laser tube cutting machines one of the indispensable equipment for manufacturing companies.

With the continuous advancement of technology, the future prospects of laser tube cutting machines are very broad. The continuous emergence of new laser technologies, such as fiber lasers and advanced control systems, has continuously improved the performance and application range of equipment. At the same time, the deep integration of automation and intelligence has also made the integration of laser tube cutting machines in production lines more efficient, promoting the optimization of the overall manufacturing process. In this context, if companies want to remain competitive, they must actively invest in advanced laser cutting technology to adapt to the rapid changes in the market and the growing customer demand.

Therefore, encouraging companies to increase investment in laser tube cutting technology is not only a necessary means to enhance their own competitiveness, but also a key measure to adapt to the future development trend of the industry. By adopting advanced laser cutting equipment, enterprises can reduce costs and achieve sustainable development while ensuring production efficiency and product quality, thus gaining an invincible position in the fierce market competition.