After the customer successfully purchased Suntop's 500W fiber laser cutting machine, our technical team responded quickly and started the installation and commissioning process of the equipment. The following are the specific steps and situations:

1. Installation process

Site preparation: Before installation, Suntop's technical team had detailed communication with the customer, confirmed the installation location of the equipment, and ensured that the on-site environment met the requirements for equipment operation, including power supply, voltage, gas source, smoke exhaust system and ground load-bearing. At the same time, a stable working environment was provided for the equipment, such as avoiding direct sunlight and good ventilation conditions to ensure the long-term stable operation of the equipment.

Transportation and handling: After precise logistics arrangements, the fiber laser cutting machine arrived at the customer's location smoothly. Our technicians inspected the equipment to ensure that there was no damage during transportation, and cleaned up the packaging materials to create conditions for subsequent installation.

Equipment installation: On site, the technical team gradually completed the installation of the laser cutting machine according to the structural requirements of the equipment. This includes placing the equipment at the predetermined location, connecting the laser generator, integrating the control system, and configuring the laser optical path. All connections strictly follow safety and technical specifications to ensure the normal operation of the equipment.

2. Debugging

Preliminary inspection: After the installation is completed, the technicians conduct a preliminary inspection of each component of the equipment to ensure that there are no hidden dangers such as looseness and broken wires. The electrical system of the equipment is systematically tested to ensure that the power supply and related control systems are operating normally.

Software system configuration: Suntop's laser cutting machine is equipped with advanced control software. During the debugging process, our technicians configured and optimized the software and matched it with the customer's needs so that the customer can achieve maximum flexibility in operation.

Cutting parameter setting: According to the material and thickness required by the customer, our technical team helps the customer set the best cutting parameters. This configuration process has been repeatedly tested to ensure that the cutting quality meets the customer's expectations. In addition, we also provide customers with a cutting parameter library for different materials so that different materials can be cut more efficiently in the future.

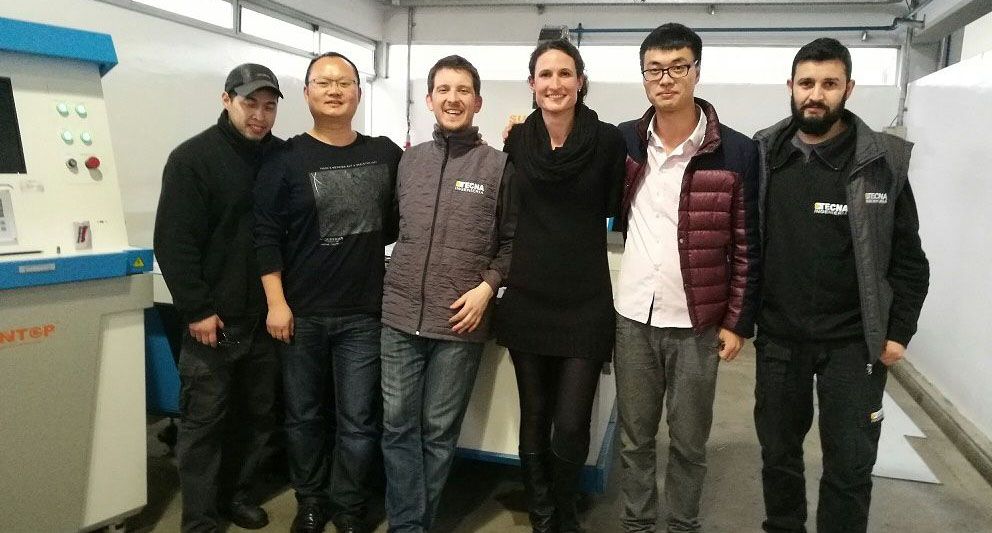

On-site training: After satisfactory debugging, the Suntop technical team also provides comprehensive on-site training for the customer's operators, including equipment operation, daily maintenance, emergency handling, etc., so that customers can fully understand how to use the equipment safely and efficiently.

3. Professionalism and service support

Suntop's technical team demonstrated its high level of professionalism and service during the installation and debugging process. Our engineers not only have rich experience in equipment installation and technical knowledge, but also maintain sensitivity to industry trends and technological advances through continuous training. In addition, we promise to provide one year of free technical support and maintenance services after the equipment is put into use to ensure that the customer's equipment always remains in the best condition in subsequent use.

Customers can contact our service team through the hotline at any time to obtain technical support or consultation. Suntop's purpose is to win customer satisfaction and trust with professional service support while providing high-quality equipment. This comprehensive service guarantee enables customers to focus on their own production processes without worrying about equipment problems, thereby achieving efficient operation. Click here for more information