1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

5. What is a steel metal laser cutting machine?

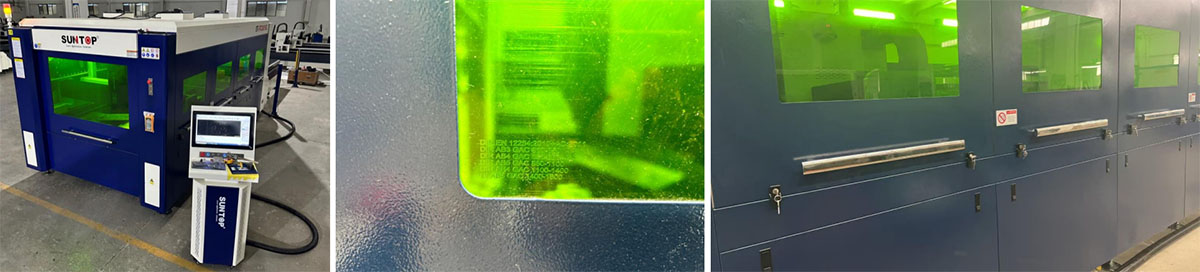

Steel metal laser cutting machine is a device that uses a high-energy laser beam to cut steel materials. It achieves precise cutting through the method of focusing and instantaneous heating. It is suitable for steel processing of various thicknesses.

6. What are the advantages of laser cutting compared with traditional cutting methods?

Laser cutting has the advantages of high precision, high efficiency, small heat-affected zone, smooth cutting edge and strong material adaptability, which can effectively reduce production costs and improve product quality.

7. What types of metal materials are suitable for laser cutting machines?

Laser cutting machines can handle a variety of metal materials, including carbon steel, stainless steel, alloy steel, aluminum, copper and its alloys, etc., and have a wide range of applications.

8. What is the maximum thickness of the cutting?

The maximum thickness that the cutting machine can handle depends on the specific model and laser power. In general, the main models can cut steel thicknesses ranging from 1mm to 25mm, and some high-power models can reach thicker materials.

9. What is the energy consumption of laser cutting?

Laser cutting is generally more energy efficient than traditional cutting technology, and can effectively reduce energy consumption and material waste, but the specific energy consumption depends on the operation mode and material thickness.

10. How difficult is it to maintain a laser cutting machine?

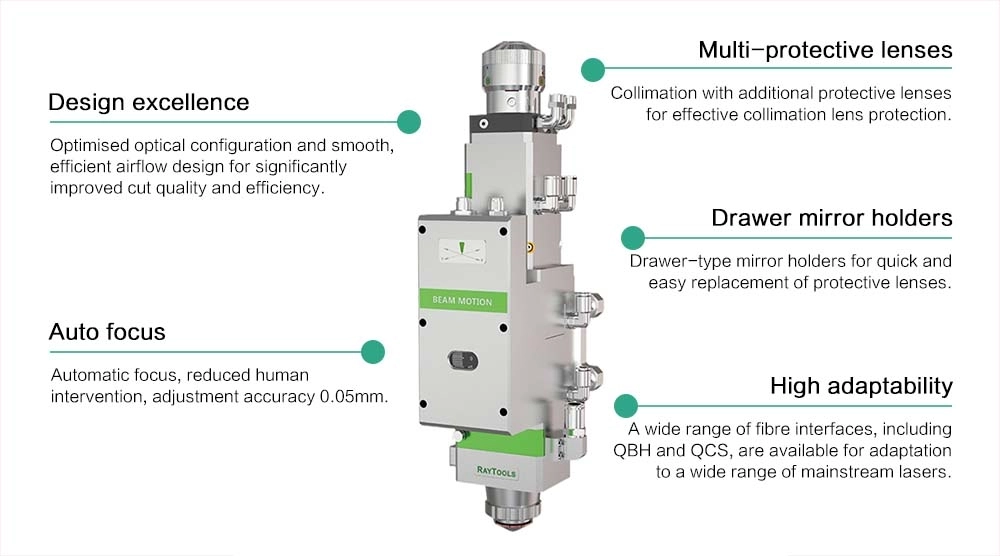

Laser cutting machines require regular maintenance, including cleaning of the laser, alignment of the optical path, and inspection of the cooling system. It is usually recommended to operate in accordance with the maintenance guide provided by the manufacturer to ensure the stability of the equipment and the cutting quality.

11. Can laser cutting be used to cut complex patterns?

Yes. Laser cutting machines can be controlled by a computer numerical control system (CNC) to achieve cutting of complex patterns and delicate designs, making them very suitable for the manufacture of customized products.

12. Are special safety measures required when using a laser cutting machine?

Yes, laser cutting generates strong beams and high temperatures, so you need to wear appropriate protective tools, such as laser safety glasses, when operating, and ensure that the work area has good ventilation and safety warning signs.

13. What is the investment cost of a laser cutting machine?

The cost of a laser cutting machine varies depending on the model, power and features, with a higher initial investment, but due to its high efficiency and low operating costs, long-term use generally provides a good return on investment.