1. Causes of oxide layer on metal surface

The oxide layer on metal surface is a substance formed by the reaction of metal with oxygen or other oxidants, and its main component is metal oxide. The main reasons for the formation of oxide layer include:

Natural oxidation: Metal reacts with oxygen in the air under normal conditions to form an oxide layer naturally. This process is affected by ambient temperature, humidity and oxygen concentration.

Electrochemical oxidation: In an environment with electrolytes, metals can be oxidized through electrochemical processes, which is common in corrosive environments. The passage of current through the metal surface promotes the occurrence of oxidation reactions.

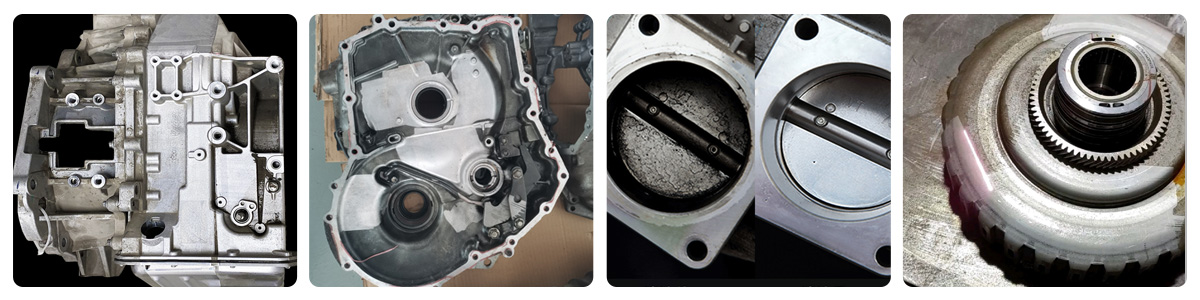

Thermal oxidation: At high temperatures, metals react with oxygen to form an oxide layer, which is particularly common in high-temperature applications (such as engine parts).

The influence of pollutants: The presence of other elements or pollutants on the surface (such as moisture, salt or oil) may accelerate the oxidation process and form different types of oxide layers.

2. Effect of oxide layer on material properties

Physical property changes: The oxide layer usually changes the surface hardness, toughness and ductility of the metal, which may cause brittleness on the metal surface and reduce its mechanical properties.

Increased corrosivity: Certain types of oxide layers may be more sensitive to environmental factors (such as humidity, acidic media, etc.), leading to accelerated corrosion and thus shortening the service life of the material.

Decreased electrical and thermal conductivity: After the oxide layer is formed, the electrical and thermal conductivity of the metal may be significantly reduced, which is particularly important in electrical and electronic components with high electrical conductivity requirements.

Decreased surface adhesion: The oxide layer affects the adhesion of subsequent coatings or bonding materials, which may cause the coating to peel or fall off, affecting the surface treatment effect.

3. The necessity of removing the oxide layer and its impact on subsequent processing and surface treatment

Improving the welding performance of materials: Removing the oxide layer can improve the cleanliness of the metal surface, improve the fusion during welding, and ensure the quality and strength of welding.

Enhancing the adhesion of the coating in subsequent surface treatment: Removing the oxide layer helps the subsequent surface treatment processes such as painting and plating, ensuring uniform adhesion of the coating and avoiding peeling and falling off.

Improving machining accuracy: Before machining, removing the oxide layer can avoid material deformation and damage caused by insufficient interlayer strength during machining, ensuring higher machining accuracy.

Extended service life: By removing the oxide layer, further corrosion and degradation are prevented, thereby extending the service life and reliability of the material.

In summary, the formation, characteristics and impact of the oxide layer on the performance of metal materials is a complex process. In many applications, removing the oxide layer is a key step to ensure the effectiveness of subsequent processing and surface treatment. Click here for more information