1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

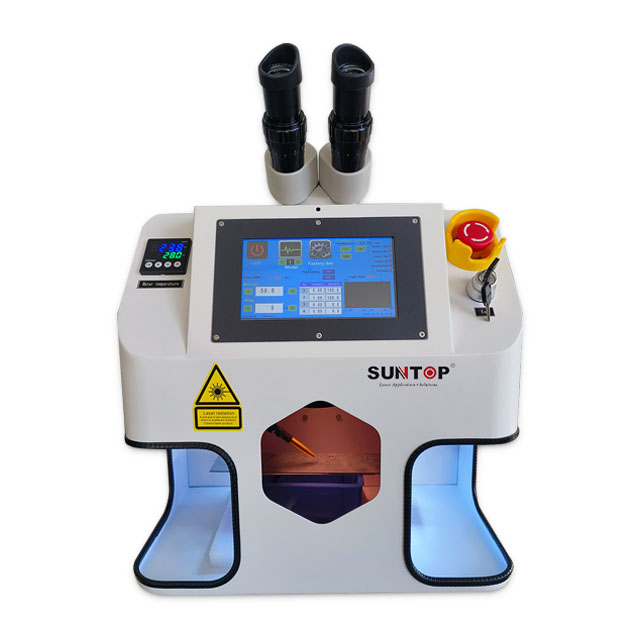

5. How does the portable mini fiber laser welding machine work?

This device precisely welds metal jewelry by emitting a high-energy fiber laser. The laser's high temperature instantly melts the metal, achieving a high-quality weld.

6. Is professional training required to operate this device?

This device is designed for user-friendliness and typically requires no professional training. Users can quickly master the basic operation and begin welding.

7. Will the welding process produce fumes or harmful gases?

Compared to traditional welding methods, this laser welding machine produces almost no fumes or harmful gases, meeting environmental standards and suitable for use in enclosed spaces.

8. What is the quality of the laser welding?

Laser welding provides high-precision welds with smooth and strong seams, ensuring the quality and aesthetics of the jewelry.

9. Is the equipment difficult to maintain and care for?

Maintenance is relatively simple. Regular cleaning of the laser head and casing is sufficient; complex maintenance procedures are generally not required.

10. Can it weld complex designs?

Yes, the portable mini fiber laser welding machine is ideal for handling complex patterns, meeting the needs of personalized and creative designs.

11. How efficient is laser welding?

This equipment offers fast welding speeds, significantly improving work efficiency and making it suitable for jewelry production and rapid repair tasks.