1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

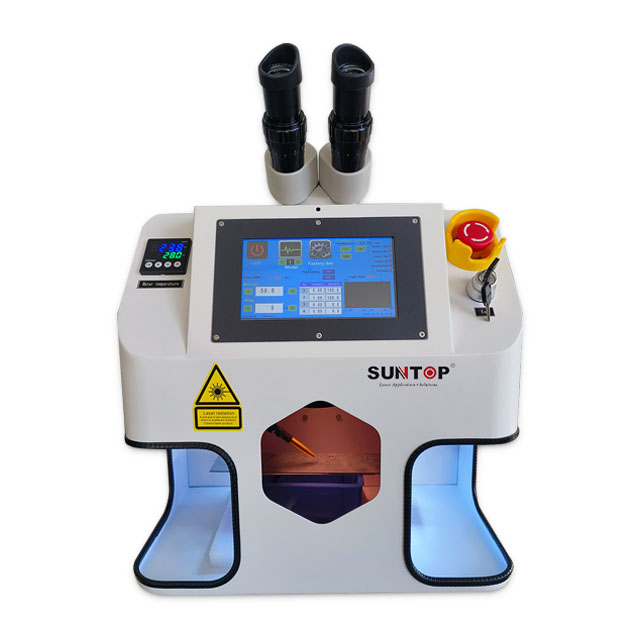

5. What is a jewelry laser welder?

Jewelry laser welder is a device that uses a high-intensity laser beam to weld metals. It is particularly suitable for achieving high-precision welding during jewelry making and repair.

6. What is the difference between laser welding and traditional welding?

Compared with traditional welding (such as electric welding or brazing), laser welding has higher precision and a smaller heat-affected zone, which reduces damage to surrounding materials, is faster, and is suitable for more complex designs.

7. How does laser welding work?

Laser welding generates high temperatures on the metal surface by focusing a laser beam, thereby melting the metal and joining the two metal parts. Because the laser can be precisely controlled, the welding area is very small.

8. Will laser welding damage gemstones?

The heat-affected zone of laser welding is relatively small and usually does not damage gemstones around the weld. However, care should still be taken during the welding process to prevent direct exposure to the high-temperature laser beam.

9. What kind of training is required to use a laser welder?

Although the operating interface of modern laser welders is relatively user-friendly, it is recommended that operators receive professional training to ensure the correct and safe use of the equipment.

10. How fast is laser welding?

Laser welding is usually fast, depending on the material and complexity of the weld. Compared with traditional welding methods, laser welding can significantly improve production efficiency.

11. How is the quality of laser welding?

Laser welding can usually achieve high-quality welding results, with smooth, neat joints and beautiful appearance. The welded joints usually do not require much post-processing.

12. What factors should be considered when purchasing a jewelry laser welder?

When purchasing a jewelry laser welder, the following factors should be considered:

Power and welding depth

Operation interface and ease of use

Equipment stability and brand reputation

After-sales service and technical support

Budget and cost-effectiveness