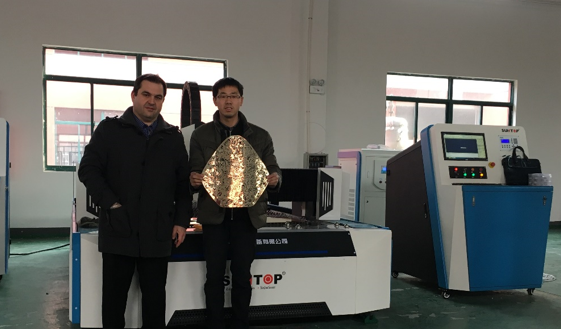

In the cooperation with French customers, the laser cut aluminum plate products delivered by SUNTOP have been highly recognized and praised by customers. The following are the specific contents of the customer feedback, highlighting the advantages of the product and customer satisfaction.

1. Recognition of product quality

The customer expressed great satisfaction with the quality of the cut aluminum plate finally delivered, which is specifically reflected in the following aspects:

High precision: The customer specifically mentioned that the cut edges of the aluminum plate were smooth and burr-free, and the accuracy of the cut size exceeded their expectations. This is crucial for their subsequent assembly work and effectively improves production efficiency.

Consistency: The consistency of all cut pieces in size and appearance has been highly recognized by customers, whether it is the uniformity of mass production or the consistency between batches, which allows them to reduce a lot of unnecessary adjustments and rework during large-scale production.

2. Optimized delivery cycle

The customer pays attention to the periodicity and time management of production, and SUNTOP effectively shortens the delivery cycle of the project. Customer feedback said that they felt SUNTOP's professional management throughout the cooperation process, and were able to respond quickly to changes in demand and ensure on-time delivery. This makes customers more flexible in production planning and reduces the downtime of the production line.

3. Customer Support and Communication

The customer appreciated SUNTOP's service team and believed that our project management and after-sales support were very good:

Fast response: The customer mentioned that any problems they encountered during the project implementation were quickly responded to by the SUNTOP team, and many questions and technical problems were solved through good communication channels.

Strong professionalism: The customer was satisfied with the professional ability of the SUNTOP team, especially in technical exchanges, the team was able to deeply understand the customer's needs and put forward practical suggestions and solutions.

4. Environmental friendliness and sustainability

The customer also highly praised SUNTOP's emphasis on environmental protection during the cutting process. The low pollution and high energy efficiency of laser cutting technology enable customers to meet higher environmental standards during the production process, demonstrating a sustainable corporate image.

5. Overall satisfaction

In general, the customer highly praised the cooperation experience with SUNTOP, expressed that they would continue to cooperate in the future, and recommended SUNTOP to other industry partners. The customer satisfaction survey results showed that customers gave 9/10 or higher ratings in multiple dimensions, indicating great satisfaction.

Through such feedback, SUNTOP not only verifies the advantages of its own technology and services, but also enhances the trust between customers and promotes long-term cooperative relations. Customer recognition will inspire us to continue to pursue excellence and meet the growing needs of customers with higher standards. Click here for more information