1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

5. How effective is laser welding?

Laser welding machines produce high-quality welds with smooth, uniform joints that are strong and typically require no post-processing. This welding method reduces deformation and stress during the welding process, thereby improving weld quality.

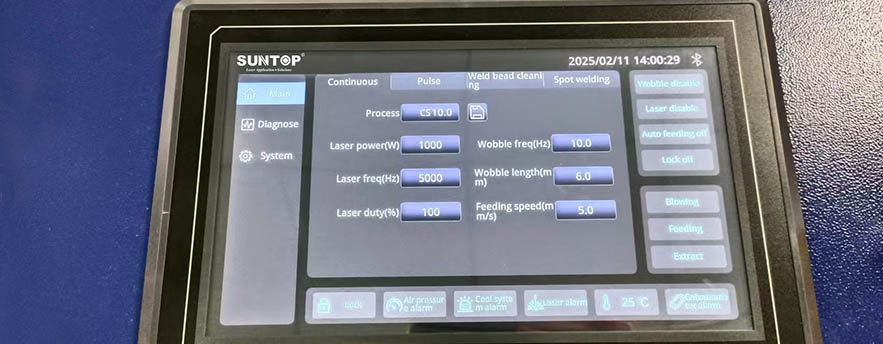

6. What professional skills are required to operate a laser welding machine?

Although modern laser welding machines are equipped with user-friendly interfaces and automated functions, operators still need to undergo professional training to ensure safe and effective use of the equipment, as well as familiarity with parameter settings and operational procedures.

7. What are the maintenance requirements for a laser welding machine?

Regular maintenance is crucial for maintaining the performance of a laser welding machine. It is recommended to regularly inspect the optical path of the laser system, clean the laser lenses, check the cooling system, and ensure software updates, among other tasks. The specific maintenance frequency should be referenced in the equipment manual.

8. How to select the appropriate laser welding machine?

When selecting a laser welding machine, multiple factors must be considered, including the type of welding material, welding mode, production scale, equipment power, and budget. Additionally, consulting professionals for advice can help identify the most suitable equipment for your specific needs.

9. What power options are available for laser welding machines?

Laser welding machines are available in power ratings of 1500W, 2000W, 3000W, and 6000W, among others. The specific choice depends on the requirements of the welding task and the characteristics of the material. Generally, higher power results in greater welding efficiency and capability.