1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

5. What are the welding results?

This equipment produces strong, smooth welds with high joint strength and a small heat-affected zone. This effectively reduces weld defects and deformation, ensuring aesthetically pleasing and durable welds.

6. What technical training is required to operate this equipment?

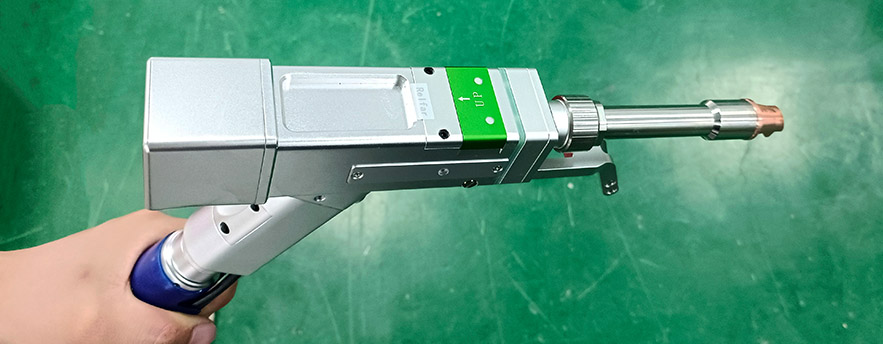

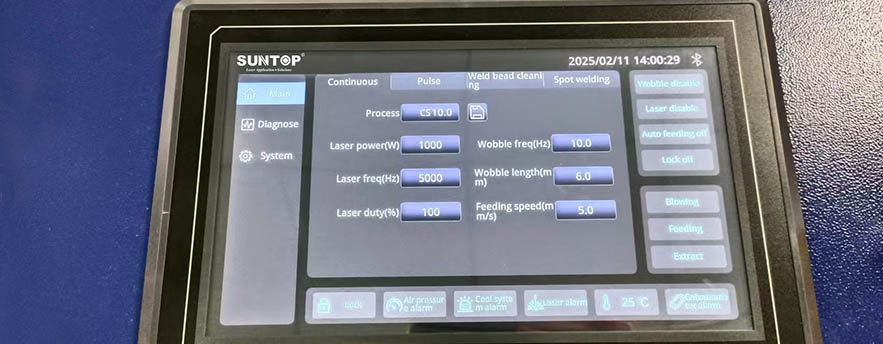

Although the 6000W handheld laser welder has a user-friendly interface, it is recommended that operators receive appropriate training to ensure safe and effective use of the equipment, including understanding welding parameter settings and safe operating procedures.

7. How does the power of the equipment affect weld quality?

Higher laser power, such as 6000W, provides higher welding speeds and penetration depths, enabling high-quality welds on thicker materials. This helps improve productivity and weld quality.

8. What are the maintenance requirements for the equipment?

Maintenance of the 6000W handheld laser welder is relatively simple, but users should regularly inspect the laser beam path and cooling system to ensure there are no contaminants that may affect laser performance. Cleaning and maintenance should be performed as necessary based on usage.

9. What are its advantages over traditional welding methods?

Compared to traditional welding methods, the 6000W handheld laser welding machine offers higher speeds, lower heat input, and less distortion. Furthermore, it reduces the need for post-processing, improving overall welding efficiency and quality.

10. Do you provide technical support and after-sales service?

Yes, we offer comprehensive technical support and after-sales service, including equipment installation, commissioning, operator training, and ongoing consulting services, ensuring customers can fully utilize the equipment's capabilities.