|

Laser sources

Features:

- Customized 45um core diameter welding version fiber laser with a service life of 100,000 hours.

- No maintenance required, can weld all types of metals.

- It has the advantages of compactness, easy integration and high energy efficiency, and is suitable for high-precision, high-speed laser welding tasks.

|

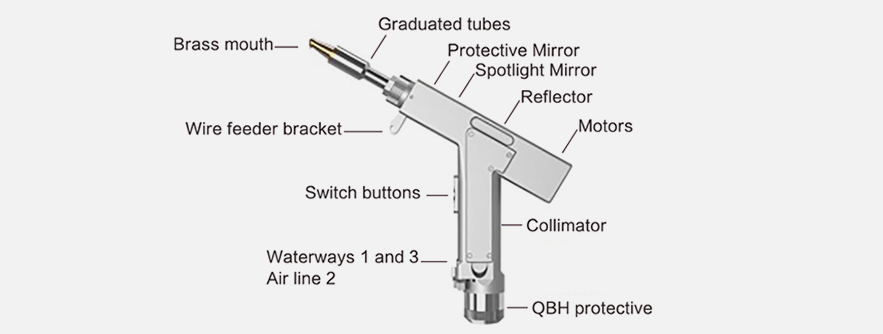

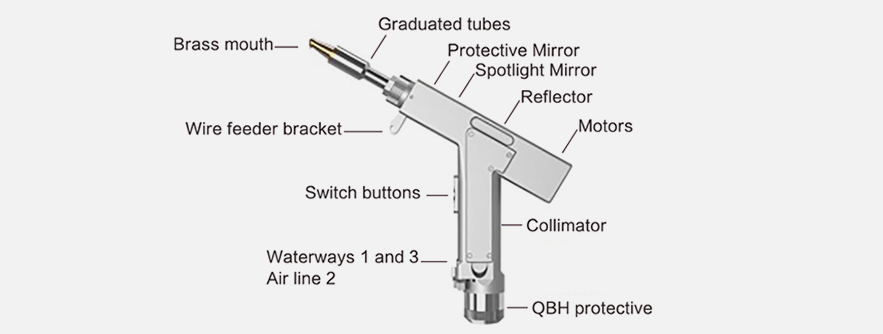

Self-developed Wobble Welding Head

Features:

- Self-developed control system and structural design, to adapt to a variety of welding needs within 3000W, set up a number of safety alarms and status indicators, the abnormal state of instantaneous response.

- Weighing only 0.7kg, it is compact and ergonomically designed, flexible operation, easy to use.

- Visualize all parameters and monitor the status of the entire machine in real-time to prevent issues, facilitate troubleshooting, ensure stable system operation.

- All process parameters can be set and various process effects can be tested flexibly.

|

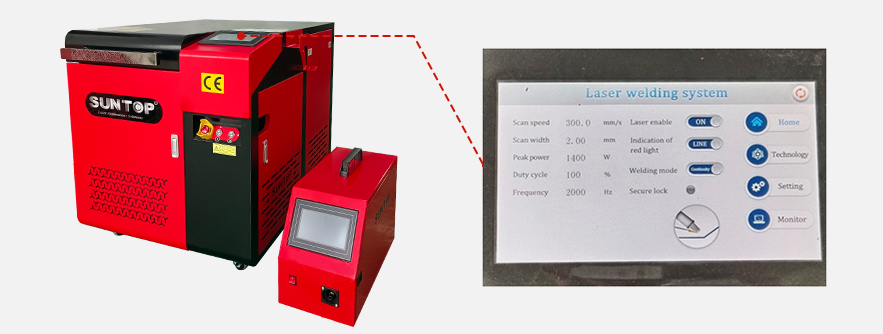

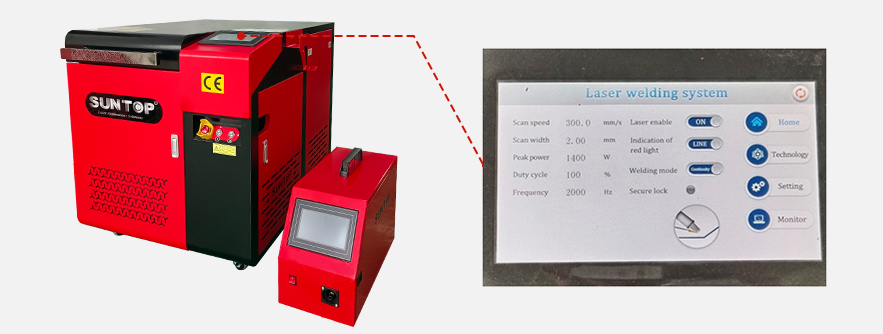

User-Friendly of Operation Interface

Features:

- Advanced resistive touch screen with higher sensitivity, intelligent control.

- Multi-language intelligent control panel, flexible adjustment of welding parameters, multi-group library of welding parameters and cumulative timing of light output etc.

- Support multiple languages (English, Spanish, German, Italian, French, Russian, Turkish, etc.)

|

Auto Welding Wire Feeder System (single/double feeder optional)

Features:

- Depending on the specific welding needs, the double wire feed can increase the width of the weld seam up to 8 mm, allowing for a high stacking effect on thicker sheet metal.

- Touch screen design, automatic wire filler, and fully digital design support stainless steel and aluminum wires with diameters of 0.8mm, 1.0mm, 1.2mm, 1.6mm, and 2.0mm.

- 220V power supply drive provides more powerful wire feeding, preventing wire jamming and resulting in more consistent welding quality.

|

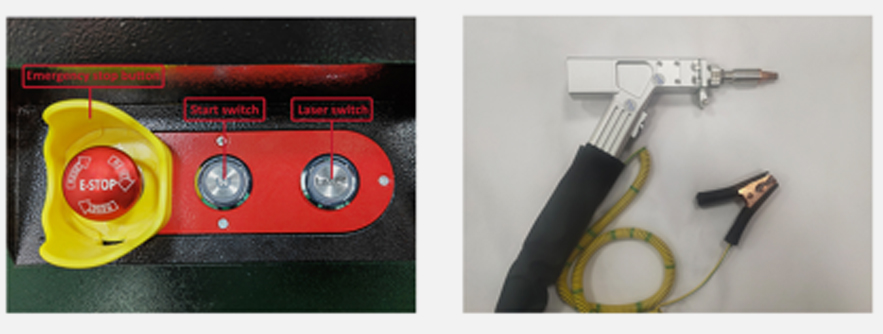

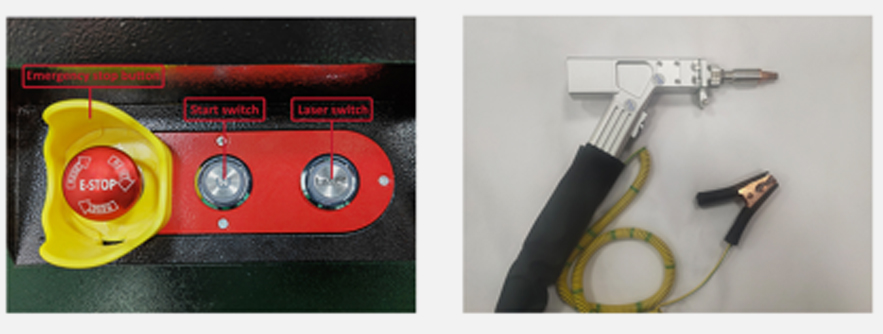

Operator Safety Features

Features:

ST-FW1500H/2000H/3000H is a Class IV laser system and routine precautions are required for the safe operation of the equipment.

Built-in features include:

- Key switch control of the laser source and an Emergency-stop button for deliberate operation.

- Fiber laser interlock to verify the integrity of laser delivery to the welding gun.

- Laser weld gun trigger for intentional operation.

- Part contact electrical interlock that turns off the laser power if the welding head is not in contact with the welded parts.

|

Cooling System

Features:

-Industrial chiller

Ensures heat dissipation of core optical path components, dual-circulation water cooling, better cooling of laser source and welding head.

-Cooling fan and temperature sensor

Add cooling fan and temperature sensor, when the temperature reaches the set temperature, the cooling fan will automatically turn on.

|

Soldering connection fiber

Features:

- By using a 10-meter original long fiber optic cable and an integrated devices, the machine becomes more compact for storage or transportation.

- - Adjust the workstation at any time, no fixed workstation required, free and flexible, suitable for welding in various working environment scenarios.

Overcome the limitations of the workbench space and realize outdoor welding and long-distance welding.