1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

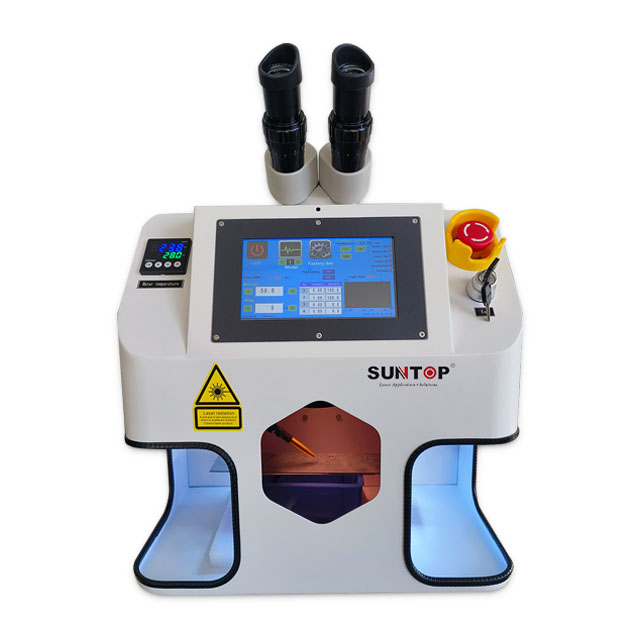

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

5. What are the advantages of the air-cooling system?

The air-cooling system improves the heat dissipation efficiency of the welding machine, extends its service life, and ensures stable welding performance even during prolonged operation.

6. How does the portable design affect performance?

Despite its portable design, the portable air-cooled laser spot welder maintains high efficiency, ensuring welding speed and quality comparable to traditional large welding machines.

7. How difficult is maintenance and upkeep?

Maintenance and upkeep of this welder are relatively simple, mainly involving regular cleaning of the optical path and inspection of the air-cooling system. Proper use and maintenance can effectively extend the equipment's lifespan.

8. Can it be used outdoors?

Yes, the portable air-cooled laser spot welder is designed for use in various environments, including outdoors, but extreme weather conditions should be avoided.