1. How can i place an order?

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For further discussion, it is better to contact us with WhatsApp / WeChat / email / phone, in case of any delays.

2. What kind of display we provide?

We have laser marking machine / laser welding machine / laser cutting machine / laser cleaning / CO2 laser cutting and engraving machine / laser accessories for you choose.

3. How about the warranty?

We have 2 years warranty and lifelong maintenance.

4. What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, DDU, DDP, etc. You can choose the one which is the most convenient or cost effective for you.

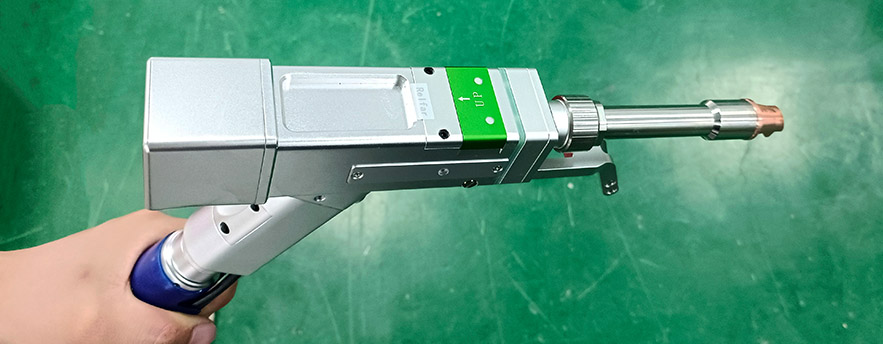

5. What is a handheld laser welder?

A handheld laser welder is a portable welding device that uses a laser beam to weld materials efficiently and precisely. It is suitable for a wide range of metal materials and can produce high-quality weld joints.

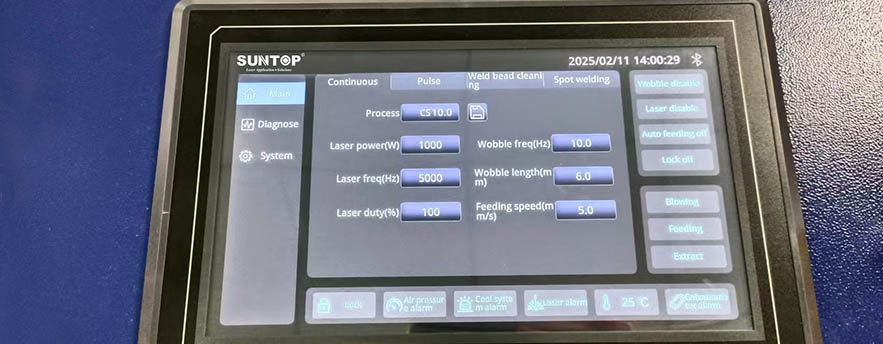

6. How difficult is it to operate a handheld laser welder?

Handheld laser welders are designed to be user-friendly and typically feature a simple interface. Users can quickly become familiar with the machine after basic training, making operation relatively simple.

7. How safe are handheld laser welders?

These machines typically have multiple safety features. When using them, be sure to follow the safety instructions and wear appropriate protective equipment.

8. Is professional training required to use a handheld laser welder?

Although handheld laser welders are relatively simple to operate, basic operating training and instruction manual study are recommended to ensure safety and weld quality.

9. What are the maintenance and service requirements for the equipment?

Handheld laser welders typically require regular cleaning of optical components and inspection of the cooling system to ensure optimal operation. Specific maintenance requirements can be found in the user manual.

10. How do I choose the right handheld laser welder?

When choosing a handheld laser welder, consider factors such as the material type and thickness, the required welding accuracy, and the working environment. Choose the appropriate power and feature configuration based on your specific application needs.