Maintaining the best performance of laser protection lenses requires regular cleaning and proper storage. The following are detailed daily cleaning and protection tips and storage recommendations to help you effectively extend the life of the lenses and keep them in optimal condition.

1. Daily cleaning and protection tips

● Cleaning frequency

Check the lenses regularly and perform necessary cleaning according to the frequency of use and environment. Especially after completing laser operation, make sure that the lenses are free of dust or stains.

● Cleaning tools

Use a soft, clean, dry cloth (such as a microfiber cloth) to clean and avoid abrasion of the lens surface.

Try to avoid using paper towels, old clothes, etc., as these materials may scratch the lenses.

● Cleaners

Use a dedicated optical cleaner and make sure it is suitable for the lens material. Never use alcohol, solvents, or cleaners containing chemicals, which may damage the lens surface.

Before cleaning the lens, you can spray the cleaner on the cloth instead of spraying it directly on the lens to prevent liquid from entering the edge.

● Cleaning steps

Gently wipe the lens with a dry cloth to remove dust and dirt.

If there are stubborn stains, spray a small amount of detergent on the cloth and keep smooth circular motions to avoid scratching the lens.

After cleaning, wipe with a clean part of the cloth to ensure that there is no residual detergent.

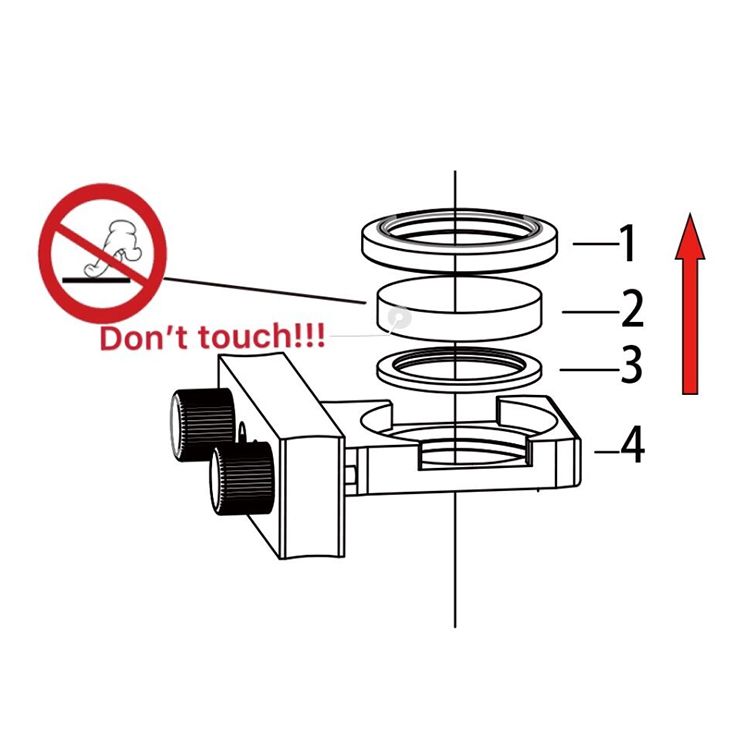

● Avoid direct contact

Do not touch the lens surface directly with your fingers to avoid grease and dirt.

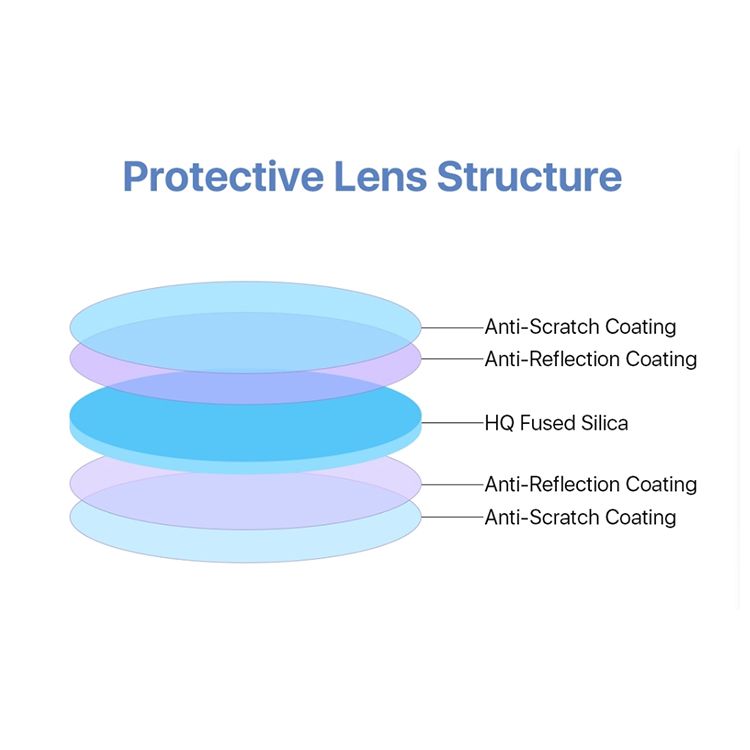

● Anti-scratch protection

When using the lens, try to keep it in the protective cover and avoid exposure to the working environment unless necessary.

2. Storage recommendations to prevent damage

● Use protective cover

Place the laser protection lens in a dedicated protective box or soft packaging to avoid compression and wear. During transportation, ensure that the lens is in a safe state to prevent accidental damage.

● Avoid high temperature and humidity

The location where the lens is stored should avoid high temperature and humidity to prevent damage to optical performance. The ideal storage environment is a place with stable temperature and dryness.

● Keep away from chemicals

Keep away from corrosive and chemicals to avoid damage to the lens material.

● Fixed storage location

When storing, ensure that the lens is away from possible falls, collisions or other unexpected factors. A dedicated shelf or cabinet can be set up to store only the lenses and related accessories.

● Regular inspection

Regularly inspect the lenses in storage to ensure that there are no scratches, stains or other damage. Deal with any problems promptly to avoid safety hazards during the next use.

By following the above cleaning and storage recommendations, you can effectively maintain the performance and safety of laser protection lenses. This can extend the life of the tool and ensure the safety and work efficiency of the operator.