Product description

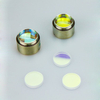

Focusing mirror is a common laser accessory on laser cutting machines. The focusing mirrors of laser cutting machines are mainly divided into aspherical focusing mirrors and spherical focusing mirrors. Although the focusing lens is a very small accessory of the laser cutting machine, it is one of its core components. Its quality will directly affect the efficiency and quality of the laser cutting machine.

Aspheric focusing lens: Focusing lens used for fiber laser cutting machines. The basic material is fused quartz material, with anti-reflective coatings on both sides. Based on the aspheric surface application, spherical aberration will not be introduced in transmission, and It can reach the ultimate diffraction performance, and a single aspherical lens can completely replace the traditional multi-piece spherical combination lens.

Spherical focusing lens: The focusing lens used in fiber laser cutting machines. The basic material is fused silica material and is coated with anti-reflective coating on both sides. To minimize spherical aberration, a two-piece combined spherical lens is usually used.

Main features

● Focusing lenses usually have one curved surface and one flat surface. The curved surface helps bend and focus the incoming laser beam.

● The focal length of a focusing lens determines the distance between the lens and the focal point. Therefore, a shorter focal length means a smaller, more tightly focused spot of light.

● The focusing lens works by converging the laser beam. Therefore, it increases the energy density of the laser at the focus.

Laser cutting machines with different powers require focusing lenses with different focal lengths

The principle of the focusing mirror is similar to that of the collimating mirror, but its convex surface faces in the opposite direction. There are many models of focusing lenses. Common focal lengths include 125 J, 150 J, 200 J, 250 J, 300 J and 350 J.

● 3000W laser cutting machine: 125 J and 150 J are available;

● 6000W laser cutting machine: 150 J and 200 J are available;

● 20,000W laser cutting machine: 200 J and 300 J are available;

● 40,000W and 50,000W laser cutting machines: 300 J and 350 J are available.

The longer the focal length, the higher the verticality of the laser, the fewer burrs during air cutting, and the easier it is to perforate thick plates. However, too long a focal length can also result in slower sheet cutting speeds.

Application of laser focusing mirror

Laser focusing lenses have been used in a variety of applications. These applications typically include:

● laser cutting

In an industrial setting, the focusing lens is part of the laser cutting machine. It helps the laser cutter focus the laser beam onto a small area of the material. Therefore, it will provide a more precise and controlled cut. The intense energy at the focal point then vaporizes or melts the material.

● laser engraving

Laser engraving involves using a focused laser beam to remove material from a surface, creating intricate designs, text or patterns. Focused lens ensures fine detail and accuracy.

● Laser Marking

Laser focusing lenses are critical in this process, concentrating the energy of the laser beam into a small focus, allowing for precise and controlled material removal or alteration. Laser focusing lenses help create a small, intense focus on the surface of the material. This precision ensures clear, well-defined markings and accurate positioning.

After using the original laser cutting machine focusing lens for a long time during the cutting process, if there are dents, film falling, scratches, etc., the cutting function of the laser equipment will be greatly reduced. If you want to perform the functions of the laser cutting machine normally, you need to replace the new focusing lens in time.

Correct installation method of focusing lens of laser cutting machine:

1. Place the protective film of the laser cutting machine focusing lens in the palm of your hand with the convex side of the lens facing up.

2. Pick up the focusing tube and carefully place it in your hand where the lens is, covering the entire lens.

3. Rotate the left and right hands 180 degrees clockwise at the same time.

4. After releasing the lens, use a small steel ruler to tighten the lens nut.

5. Install the jet cup on the focusing tube of the laser cutting machine.