Product Details Product Parameters Samples Video

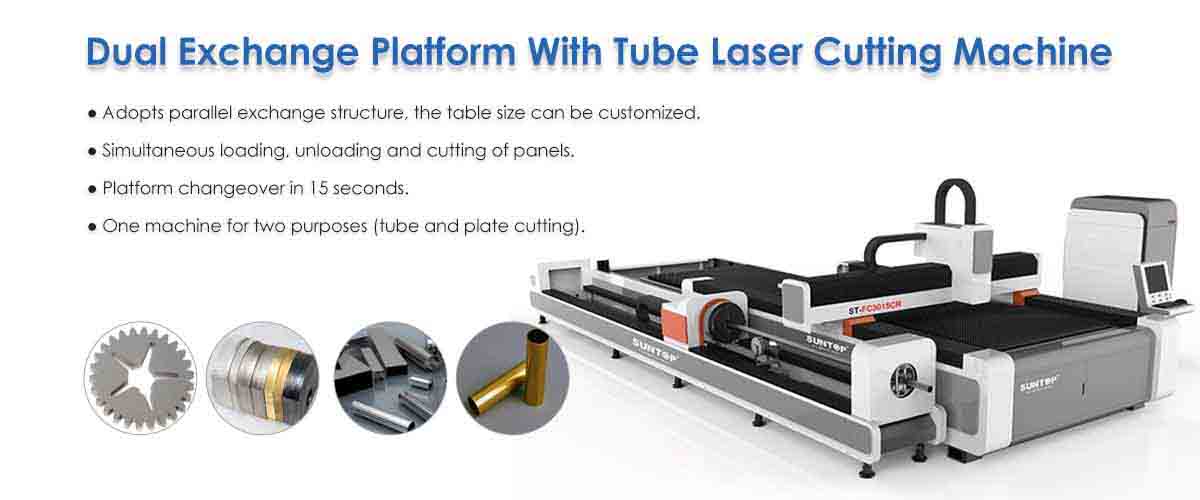

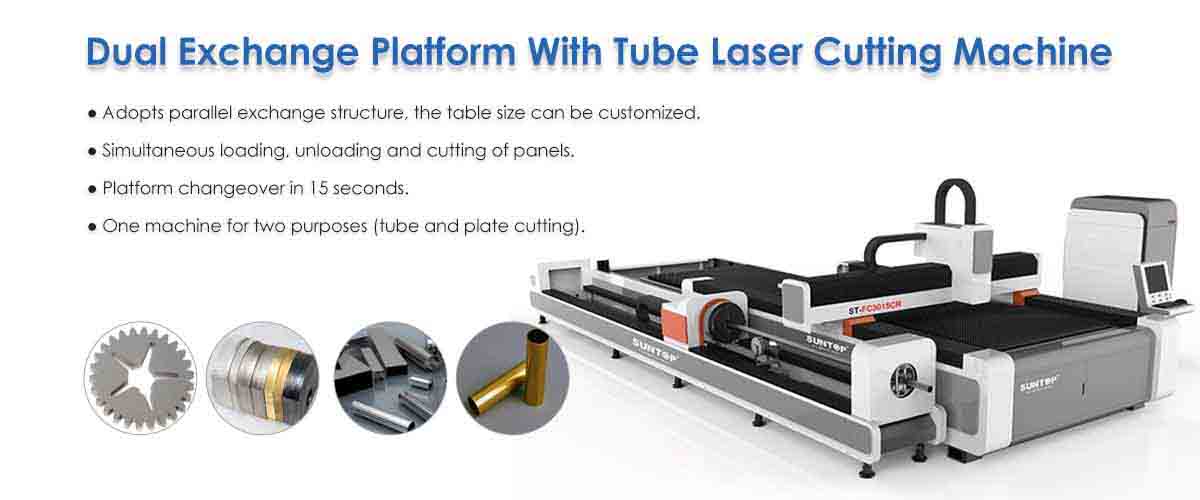

Dual Exchange Platform with Tube Cutting main features

* The machine adopts parallel exchange structure, the table size can be customized.

* The machine is equipped with pneumatic rotary axes for cutting square, round, rectangular and channel steel tubes, with automatic clamping, pushing and positioning of the central power for true intelligence.

* The pipes & tubes length and size can be customized according to customer requirements.

* Simultaneous loading, unloading and cutting of sheet metal plates from which greatly increases work efficiency;

* The converter is responsible for controlling the exchanging motor;

* The machine is able to finish the platform exchanging within 15s.

* Heavy-duty machine structure with cross-welded steel plates to support later laser power upgrades;

* The machine can be fully enclosed according to customer requirements.

Suntop Tube and Plates Fiber Laser Cutting Machine the key technology & advantages

a, the whole machine tool is made of thick carbon steel structure with the staggered honeycomb welding, which is machined roughly after stress annealing and then the vibration aging treatment is performed. The natural aging may completely eliminate the welding and machining stress. With good rigidity and high precision, it may maintain normal use for 20 years without deformation,the result is an excellent guarantee of cutting accuracy.

b, we adopt the first generation Gantry which with steel plate welding structure (section bar and sheet material welding structure is used), due to large density of the Iron and steel, its weight is about 3 times than of the aluminium with the same volume; The heavier the weight, the greater the inertia, the power motor drive with great inertia is required.

c, All france Schneider original devices are used for MCB relays, each control circuit is controlled separately, and multiple Schneider aire circuit breakers are used without interfeerence from strong power. The industrial-grade industrial control host, the software system runs stably and smoothly without crashing.

d, Suntop laser cutting head lifting (Z axis) adopts closed module, fully sealed protection effectively prevents cutting dust and smoke from entering the module, avoiding and reducing the failure tate. Internal integrated ball screw, linear guide, etc, high integration, small size and high running accuracy etc..

e, Suntop patented design of universal shaft drive table interchange method, good synchronization performance, large exchange torque, strong resistance to overload, long-term reliable operation, no failure. Equipped with a high power mid-mounted 3KW motor with a brake system and hard toothed surface reducer, the torque output is large, the torque transmission of the symmetrical 80mm diameter universal shaft, and the double 16mm chain drag table.

f, Suntop laser cutting machine are designed with stainless steel protective organ cover from which effectively prevents cutting sparks from burning out the organ cover and full protection effectively protects the rack of the guide rail from mechanical dust and foreign matter.

g, the shortest blade spacking in the industry of encrypted thickeded blade design is 5cm, ensure that the worktable has a strong bearing capacity to process thicker plates without collapse, and evenly process the thin plates without deformation etc. Slag dropping smoothly reduces the probability of plate warping and improves processing stablility.

Dual Exchange Platform with Tube Cutting application industry and materials

Fiber Laser Cutting Machine has been widely used in manufacture billboard, sheet metal structure, high-low voltage electric cabinet, textile machinery, kitchenware, tubing, lighting, kitchen and bathroom, electrical industrymetal artware, etc; Processing material like carbon steel, stainless steel, aluminium, brass, copper etc.