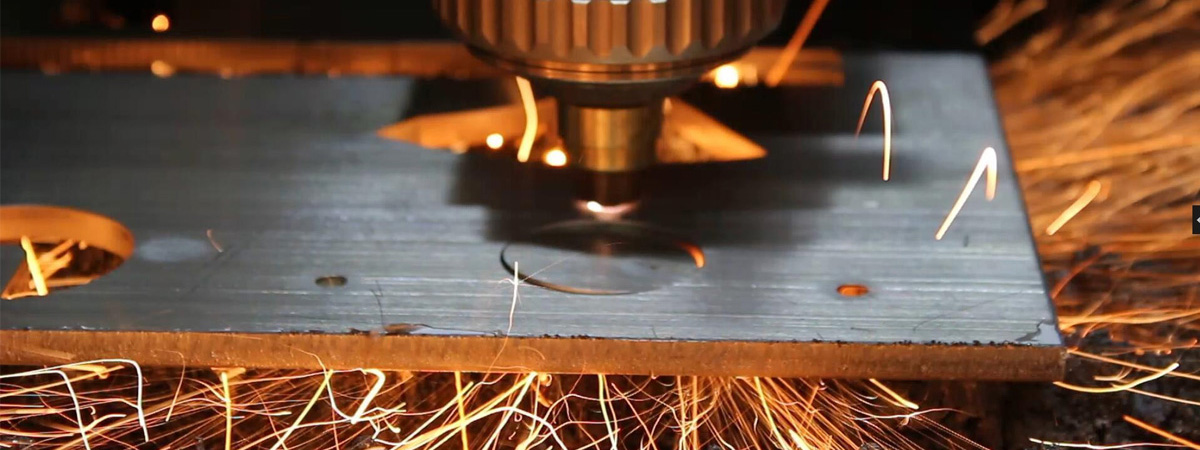

With the development of technology and the increasing demand of consumers for high-performance electronic products, the precision electronics industry has shown a strong demand for laser cutting technology in many aspects.

1. High-precision processing requirements

Microstructure processing: Precision electronic products (such as mobile phones, tablets, smart watches, etc.) usually have complex microstructures and miniaturized designs. Laser cutting technology can achieve micron-level cutting accuracy, which can meet the high requirements of these products in design and function.

High-quality edge processing: Laser cutting provides smooth cutting edges and a smaller heat-affected area, reducing the need for subsequent processing (such as grinding and deburring). This is essential for maintaining the function and reliability of electronic components.

2. Processing capabilities of diverse materials

Multiple material adaptability: The materials used in the precision electronics industry are diverse, including metals (such as aluminum, copper, nickel, etc.), plastics, composite materials, etc. Laser cutting technology can flexibly process a variety of materials to meet the needs of different products.

Unleashing the potential of new materials: With the continuous emergence of new materials, laser cutting makes the application of these new materials in electronic products possible, thereby promoting innovation and development in the industry.

3. Improve production efficiency and reduce costs

Fast processing capability: The high cutting speed of laser cutting is crucial for large-scale production, which can effectively improve production efficiency and shorten production cycle. This provides an advantage for precision electronics companies in the fierce market competition.

Reduce material waste: The precise cutting of laser cutting can minimize material waste, reduce production costs, and improve resource utilization. This is particularly important in the modern environment that emphasizes sustainable development.

4. Flexible production mode

Quick response to market demand: Precision electronic products often need to quickly adjust the design and production plan according to market changes. Laser cutting technology can adapt to different cutting needs through simple program adjustments, making production more flexible and efficient.

Advantages of small batch production: In the case of small batch and multi-variety production, laser cutting can quickly adapt to different requirements without expensive mold investment, reducing the economic pressure of enterprises in the early stage of product development.

5. Strengthen product functions

Functional integration: Modern precision electronic products often integrate multiple functions, such as sensors, antennas, etc. Laser cutting technology can perform multi-level and multi-functional processing on the same material, promoting the intelligence and complexity of products.

Miniaturization trend: As electronic products become increasingly miniaturized, laser cutting technology will help achieve more complex and compact designs and promote the industry's development in miniaturization technology.

In the precision electronics industry, laser cutting technology meets the growing demand for high-precision, high-efficiency and diversified processing, and promotes the improvement of product quality and production efficiency. With the continuous advancement of the industry, the application of laser cutting technology will become more and more extensive, becoming an important driving force for innovation and development in the precision electronics industry. Click here for more information now